77

REGULAR CHECKS AND MAINTENANCE WORK

3. Grease at each 90 (1.58 rad.) position of the pitch

bearing. Using the grease gun , apply 5 shots at every

position. Refer to the "RECOMMENDED OILS"

section.

B

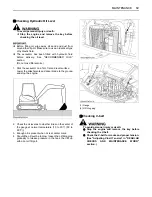

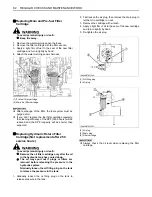

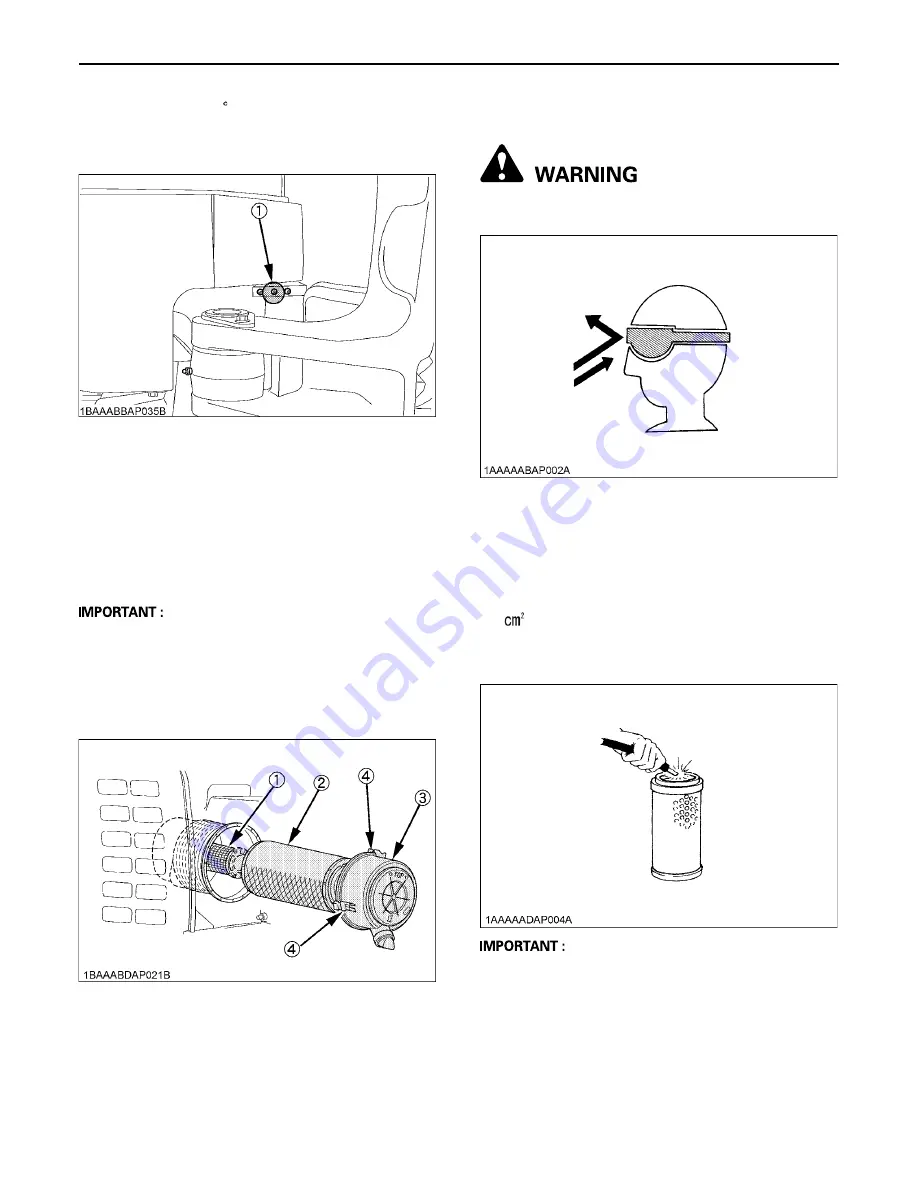

Inspection and Cleaning Air Filter Element

Open the engine hood and remove the dust-cover. Take

out only outer element, clean the element, case interior

and reassemble. During reassembly, take care to install

the dust-cover so that its TOP mark (arrow) faces up-

wards. Do not remove the inner element.

A

Should the machine be used in extremely dusty areas,

the air filter element must be inspected and cleaned

more frequently than in the specified maintenance

periods.

A

The air filter has a dry element, keep free from oil.

A

Do not run the engine without the air filter.

B

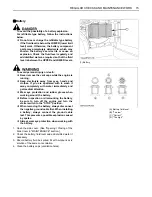

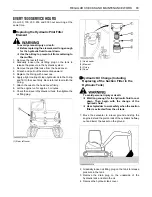

Air Filter Maintenance

To avoid personal injury or death:

A

Wear eye protection.

The quickest and safest method of maintenance is the

exchange of the paper cartridge. Furthermore there are

different methods of cleaning the cartridge.

C

Cleaning with compressed air

Pressure of compressed air must be under 205 kPa (2.1

kgf/

, 30 psi), and the cartridge should be blown clean

from the inside to the outside until the dust deposits are

noticeably reduced.

A

If the air suction is still inadequate, or the color of the

exhaust gases is abnormal even after the cleaning, the

air filter cartridge must be replaced.

(1) Grease fitting

(1) Inner element

(2) Outer element

(3) Dust-cover

(4) Clamps

Содержание KX080-4S

Страница 10: ......

Страница 18: ...SAFE OPERATION 8 ...

Страница 19: ... 9 SAFE OPERATION ...

Страница 20: ...SAFE OPERATION 10 ...

Страница 21: ... 11 SAFE OPERATION ...

Страница 22: ...SAFE OPERATION 12 ...

Страница 23: ... 13 SAFE OPERATION ...

Страница 26: ...DEALER SERVICE 2 1 Engine serial No ...

Страница 71: ...47 EXCAVATOR OPERATION ...

Страница 130: ...106 LIFTING CAPACITY ...