moviBOOST VP

5

Installation at site

5.1

Readiness for operation

The owner or the owner’s representative must report the unit’s

readiness for operation to the responsible authorities (normally

either the water company or the Trade Inspection Office). Prior

to commissioning, the installation contractor must demonstrate

conclusively that the installation requirements have been

complied with.

The power supply line must be installed / connected by a duly

authorised company.

5.2

Installation and location

The moviBOOST must be located either in the technical

equipment room or in a well-ventilated, frost-free, lockable

room used for no other purpose. No harmful gases are allowed

to enter the place of installation. An adequately sized drain

connection (leading to a sewer or equivalent) must be provided.

The unit is designed for a maximum ambient temperature of

0

0

C to +40

0

C at a relative humidity of 50%.

moviBOOST units should not be installed next to sleeping or

living quarters.

Thanks to the anti-vibration mounts, the moviBOOST VP unit

is adequately insulated to prevent transmission of solid-borne

noise.

5.3

Piping

All piping must be installed without transmitting any stresses

or strains. The use of length-limited expansion joints is

advisable (see Accessories).

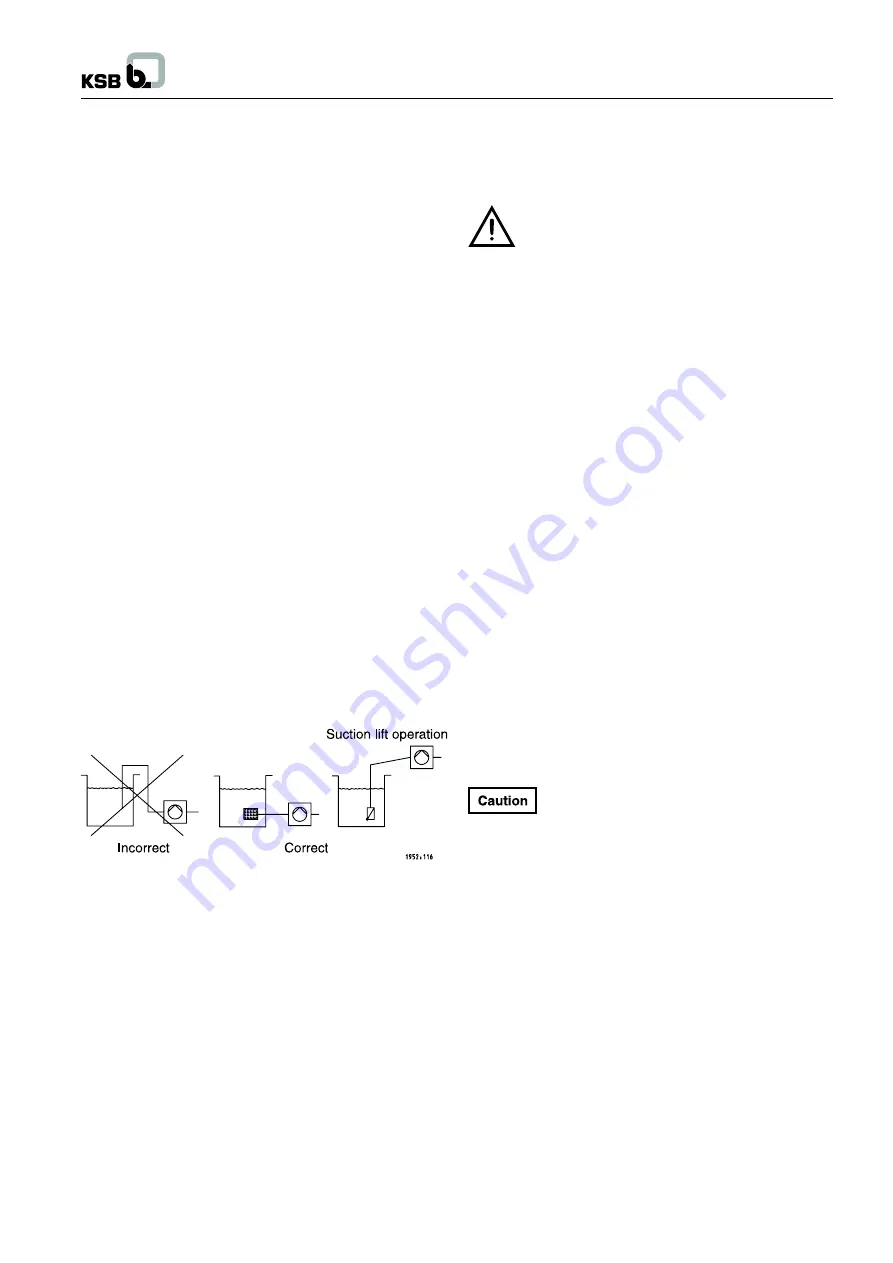

The formation of air pockets must be avoided. For suction lift

operation, the suction side piping must be laid with a

continuously rising slope.

5.4

Foundation

The package unit is designed for installation on a level

concrete floor. Its anti-vibration pads provide adequate

insulation against solid-borne noise.

5.5

Location

Prior to installing the unit, remove the packaging.

Connect the unit’s inlet and discharge pressure lines with the

corresponding distribution lines.

In order to avoid transmission of piping forces onto the system

and transmission of solid-borne noise, we recommend

installing length-limited expansion joints.

The unit must be accessible to allow maintenance and repair

work.

5.6

Installing a pressure reducer

A length of approximately 600 mm must be provided on the

inlet pressure side to accommodate a pressure reducer, if

necessary.

A pressure reducer must be installed if the inlet

pressure fluctuation is so high that the PBU must be

stopped or if the total system pressure (inlet pressure

plus shut-off head) exceeds the design pressure.

The maximum pump discharge pressure at zero flow point is

reached in manual mode.

For the pressure reducer to function properly, there must be a

minimum pressure gradient of 5 m. The pressure downstream

of the pressure reducer (downstream pressure) is the basic

parameter for defining the pump head.

Example :

The inlet pressure fluctuates between 4 and 8 bar. A pressure

reducer is needed upstream of the unit on the inlet pressure

side.

Min. inlet pressure (H

vor

) = 4 bar

Minimum pressure gradient = 0.5 bar

Downstream pressure = 3.5 bar

5.7

Location and installation of unpressurised

inlet tanks

5.7.1 Location

Inlet tanks may be installed in the same location as the

pressure boosting unit. Installation and location are governed

by the rules applicable to the pressure boosting unit (see 5.2).

5.7.2 Installation

The closed PE inlet tank (under atmospheric pressure)

available as an accessory must be installed as described in

the installation instructions supplied with the tank.

Mechanical and electrical installation of the tank must be

completed prior to commissioning of the unit.

Clean the tank before filling it.

5.8

Valves and fittings

All other valves and fittings in the service pipes, e.g. gate

valves, water meters and non-return valves must be sized in

accordance with the data provided by the responsible water

company.

5.9

Noise characteristics

moviBOOST VP units are available with different pump models

in variable numbers.

Therefore, the total sound pressure level in dB(A) needs to be

calculated.

For the noise level of the individual pumps refer to the pumps

Operating Instructions.

5

Содержание moviBOOST VP

Страница 1: ......

Страница 12: ...moviBOOST VP 7 5 2 Menu structure Main menu KSB logo actual value display 10 ...

Страница 14: ...moviBOOST VP 7 7 Parameter list 12 ...

Страница 15: ...moviBOOST VP 13 ...

Страница 16: ...moviBOOST VP 14 ...

Страница 17: ...moviBOOST VP 15 ...

Страница 18: ...moviBOOST VP 16 ...

Страница 19: ...moviBOOST VP 17 ...

Страница 23: ...moviBOOST VP 21 15 Electrical performance data ...

Страница 24: ...moviBOOST VP 16 Shutoff head 22 ...

Страница 29: ...moviBOOST VP NOTES ...

Страница 30: ......