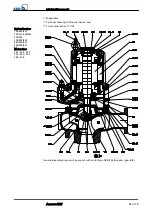

6. Lift off the pump set and adjust the axial clearance to 0.3 ± 0.1 mm.

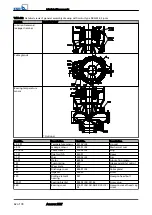

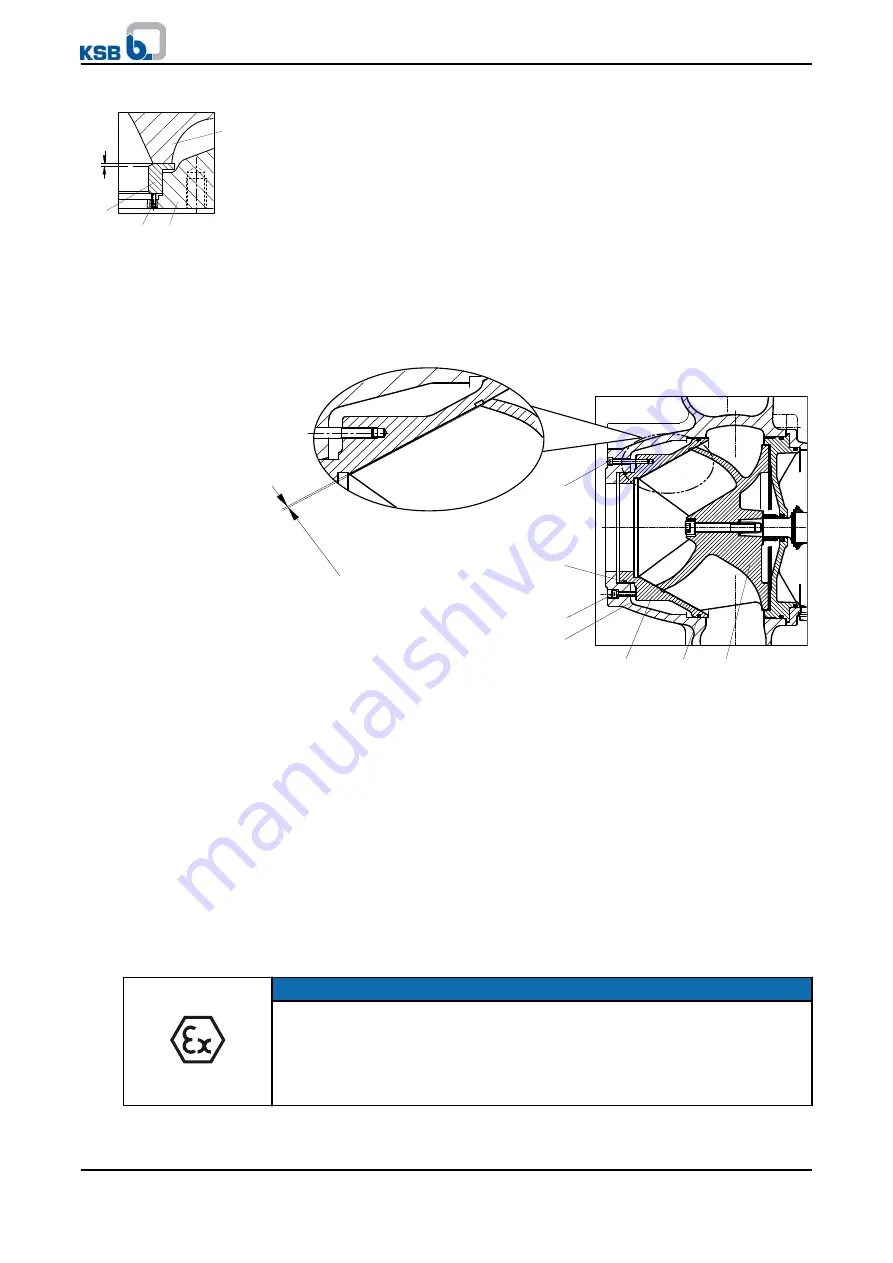

7.5.2.3.2 Design with wear plate

✓

The shaft, rolling element bearings, mechanical seal and impeller have been

assembled properly.

0.4

+0.2

mm

914.12

412.34

914.24

135

412.33

230

101

Fig. 33: Fitting the wear plate

1. Equip wear plate 135 with two new O-rings 412.33 and 412.34.

2. Insert wear plate 135 into pump casing 101.

3. Fasten wear plate 135 to pump casing 101 with socket head cap screws 914.12.

4. Adjust the clearance between impeller 230 and wear plate 135 by loosening and

tightening screws 914.12 and 914.24.

⇨

Screw 914.24 pushes the wear plate in the direction of the impeller.

⇨

The clearance equals 0.4

+0.2

mm (measured on the suction side from the

outer surface of the impeller vane to the wear plate).

5. Insert the complete back pull-out unit into the pump casing.

6. Evenly tighten screwed connection 920.01 between pump casing and bearing

bracket.

7.5.3 Reassambling the motor section

NOTE

Before reassembling the motor section, check that all joints relevant to explosion

protection (flamepaths) are undamaged. Any components with damaged flamepaths

must be replaced. Only use original spare parts made by KSB for explosion-proof

pumps. Observe the flamepath positions specified in the Annex. Secure all screwed

connections closing off a flameproof enclosure with a thread-locking agent (Loctite type

243).

502

904.01 101

230

A

Fig. 32: Fitting the casing

wear ring

7 Servicing/Maintenance

Amarex KRT

53 of 78

Содержание Amarex KRT

Страница 77: ......