thermistors with terminals 10 and 11 must be used. They must be connected to a

thermistor tripping unit with manual reset and ATEX approval for monitoring the

temperature of explosion-proof motors in "flameproof enclosure Ex d" type of

protection.

5.4.1.4.2 Leakage inside the motor

PE

K 1

9

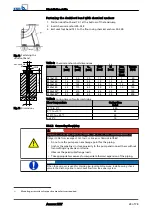

Connecting the electrode relay

B2

Position of the electrode in the motor housing

An electrode fitted inside the motor monitors the winding and connection space for

leakage. This electrode must be connected to an electrode relay (core identification

9). Tripping of the electrode relay must result in the pump set cutting out.

The electrode relay (K1) must meet the following requirements:

▪

Sensor circuit 10 to 30V ~

▪

Tripping current 0.5 to 3 mA

(equivalent to a tripping resistance of 3 to 60 k

Ω)

5.4.1.4.3 Leakage at the mechanical seal (only for pump sets with reinforced

bearings)

The chamber for mechanical seal leakage is equipped with a float switch (core

identification 3 and 4). The contact (maximum 250 V~/2 A) opens when leakage is

detected in the leakage chamber. Opening of the contact shall trigger an alarm

signal. (

5.4.1.4.4 Bearing temperature

As an option, the pump set can be supplied with temperature monitoring in the area

of the lower bearing.

Check in the data sheet whether the pump set is equipped with bearing temperature

monitoring.

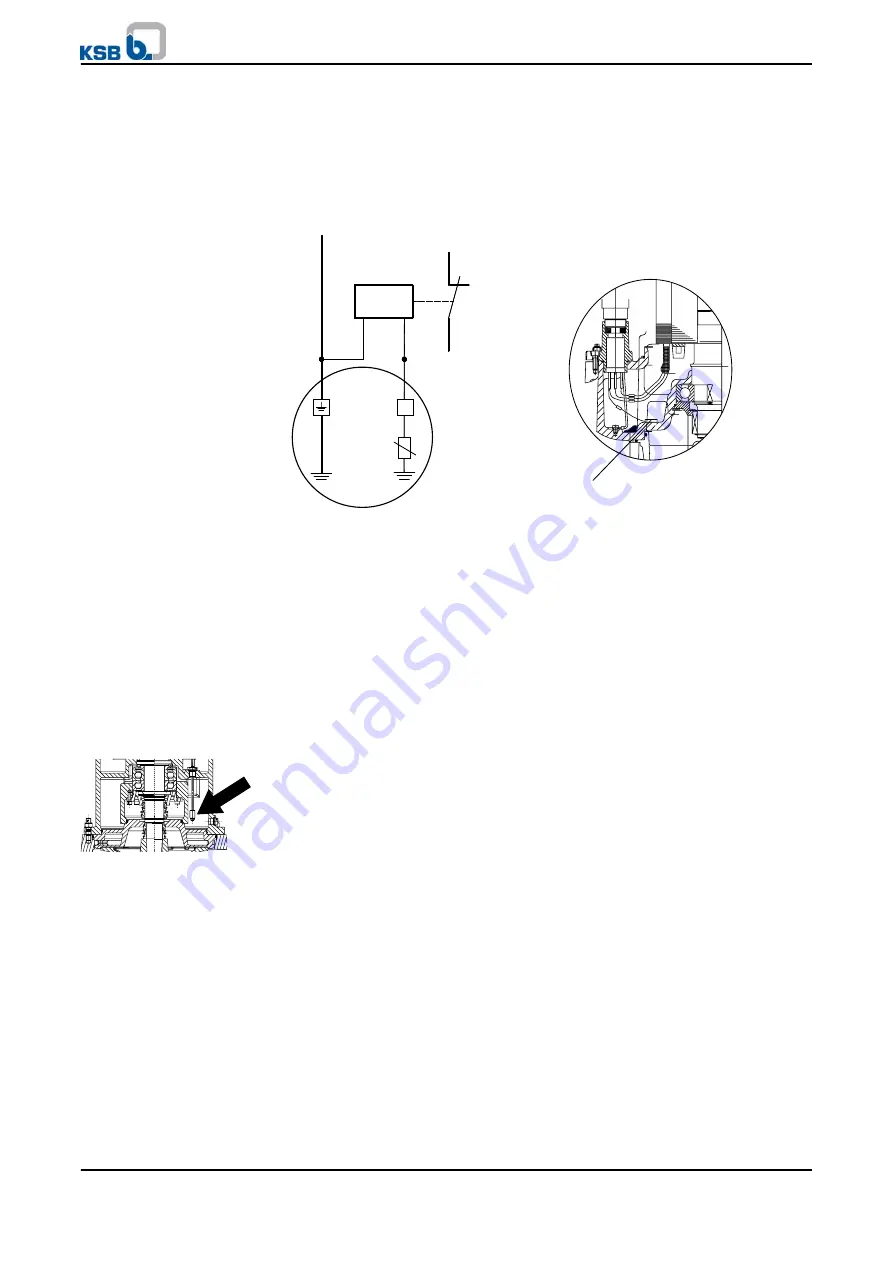

The bearing temperature sensor is a PT100 resistance thermometer. It has to be

connected to a temperature control device with a PT100 input and 2 separate

outputs for two different switching points (sensor circuit maximum 6V/2mA).

Set the following limits:

▪

Alarm at 110 °C

▪

Cut-out of the pump set at 130°C

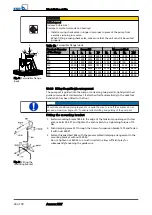

Fig. 17: Float switch

5 Installation at Site

Amarex KRT

31 of 78

Содержание Amarex KRT

Страница 77: ......