GB-5

D

GB

F

NL

I

E

▷

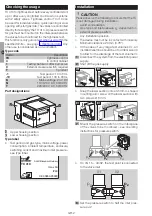

Press the reset button, see page 4 (Com-

missioning).

▷

If the tightness control will not start even though

all faults have been remedied, remove the unit

and send it to the manufacturer for inspection.

? Fault

! Cause

• Remedy

? No LED is lit although mains voltage and

ϑ

signal are applied?

!

Fuse defective.

•

Replace 5 A slow-acting fine-wire fuse – after

replacing the fuse, start the tightness test several

times and check the program sequence and the

outputs of the tightness control.

•

If it does not operate correctly, return the unit to

the manufacturer.

! Mode :

test before burner start-up is set; L1

and N are reversed on terminals 1 and 2.

•

Connect L1 to terminal 1 and N to terminal 2.

!

For 24 V DC: polarity of mains voltage on termi-

nals 1 and 2 reversed.

•

C to terminal 1 and – to terminal 2.

!

Mains voltage too low.

•

Compare to details on the type label. Tolerance:

-15/+10% for 110/120 V AC and 220/240 V AC,

±20% for 24 V DC.

? TC repeatedly signals a fault?

!

A valve is leaking.

•

Replace the valve.

!

Pressure switch incorrectly set.

•

Set the pressure switch to half the inlet pressure.

!

Wiring to the valves reversed.

•

Start the program and observe the interspace

pressure p

z

. The pressure must change during

the TEST phase. Check the wiring.

!

Inlet pressure p

u

< 10 mbar.

•

Provide the min. inlet pressure of 10 mbar.

!

Interspace pressure p

z

cannot be reduced.

•

The volume downstream of the valve on the

burner side must be 5 times higher than the

volume between the valves and atmospheric

pressure must prevail.

!

The test period t

P

is too long.

•

Adjust t

P

, see page 3 (Setting the test pe-

? The downstream automatic burner control

unit does not start?

!

On the tightness control, L1 (+) and N (–) on

terminals 1 and 2 are reversed.

•

Connect L1 (+) to terminal 1 and N (–) to termi-

nal 2.

? TEST phase running (yellow LED indicator is

lit) although no

ϑ

signal has been applied?

!

Mode 2 set.

•

Set jumper to Mode 1, see page 3 (Setting

the test instant).

Maintenance

Tightness controls TC require little servicing. We rec-

ommend a function check once a year.

Technical data

Mains voltage:

110/120 V AC, -15/+10%, 50/60 Hz,

220/240 V AC, -15/+10%, 50/60 Hz,

24 V DC, ±20%.

Power consumption:

10 VA for 110/120 V AC and 220/240 V AC,

1.2 W for 24 V DC.

Ambient temperature: -15 to +60°C (5 to 140°F),

no condensation permitted.

Storage temperature: -15 to +40°C (5 to 104°F).

Screw terminals 2.5 mm

2

.

Fusing: fine-wire fuse 5 A, slow-acting, H pursuant

to IEC 127, also protects the valve outputs and

external operating signal.

Switching current for valves/enable output:

max. 5 A.

External operating signal: with mains voltage,

max. 5 A resistive load (UL listed: 5 A for 120 V),

max. 2 A at cos

ϕ

= 0.35 (pilot duty).

Fault output: dry contact (not internally fused),

max. 1 A for 220/240 V, max. 2 A for 120 V.

Reset: using a button on the device.

Remote reset: by applying mains voltage

(terminal 5).

Housing made of impact-resistant plastic.

Gas type and inlet pressure: dependent on exter-

nal pressure switch.

Test period t

P

: TC 410-1: 10 to 60 s, adjustable.

Set at the factory to 10 s.

TC 410-10: 100 to 600 s, adjustable. Set at the

factory to 100 s.

Enclosure: IP 40.

5 knock-out holes for M16 plastic cable glands.

Weight: approx. 400 g (0.88 lbs).

Designed lifetime

Max. service life under operating conditions: 10 years

after date of production or 250,000 operating cycles

pursuant to EN 1643.