GB-4

D

GB

F

NL

I

E

Valves

Valve

volume

V

V

[l]

Nominal

size

DN

Pipe

volume

V

R

[l/m]

VK 125

13.6

125

12.3

VK 150

20

150

17.7

VK 200

42

200

31.4

VK 250

66

250

49

VAS 1

0.08

VAS 2

0.32

VAS 3

0.68

VAS 6

1.37

VAS 7

2.04

VAS 8

3.34

VAS 9

5.41

VCS 1

0.05

VCS 2

0.18

VCS 3

0.39

VCS 6

1.11

VCS 7

1.40

VCS 8

2.82

VCS 9

4.34

Calculation example:

Q

max.

= 100 m

3

/h

p

u

= 100 mbar

V

P

= V

V

+ L x V

R

= 7 l

Q

L

= 100 m

3

/h x 0.1% = 100 l/h

4 x

(

100 x 7

+ 1 s

)

= 32 s

100

Set the next highest value (in this example 40 s)

with the jumper.

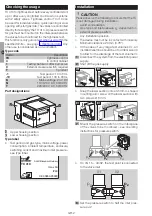

Disconnect the unit from the electrical power

supply.

Unscrew the housing cover.

4

Connect the jumper to the pin for the required

test period t

P

between 10 and 60 s (100 and

600 s).

V2

V1

L1(+)

N(-)

ϑ

max

N

1 2

1 2

"TEST

:

"

TEST"

:"

5

Position the housing cover and screw tight.

6

Mark the set test period t

P

on the type label with

a waterproof pen.

TC

CE-0085AP0020

tp(s) 10 20 30 40 50 60

D-49018 Osnabrück, Germany

Commissioning

▷

Indicators and operating controls:

TEST OK

1

2

TEST

= TEST phase (yellow)

OK

= operating signal (green)

1

= fault valve 1 (red)

2

= fault valve 2 (red)

= reset button

Main switch on.

Apply mains voltage to terminal 1.

▷

If one or both fault lamps (red) are lit, wait ap-

prox. 5 s then press the reset button. The fault

signal goes out.

Start the tightness test.

▷

Mode

, test before burner start-up.

4

Voltage at terminal 3.

Or

▷

Mode

, test after burner run.

5

Mains voltage at terminal 1 and renewed test

after switching off the voltage to terminal 3.

The test begins:

▷

LED

TEST

is lit.

After test, if the valves are tight:

▷

LED

OK

is lit.

MODE 1: voltage at terminal 4.

Or

MODE 2: voltage at terminal 4 does not arrive

until voltage is applied to terminal 3.

After test, if the valves are leaking: voltage at termi-

nals 8 and 9.

▷

LED

1

is lit.

Or

▷

LED

2

is lit.

Power failure

▷

If the power fails briefly during the test or during

operation, the tightness test will restart auto-

matically.

▷

After a power failure during a fault, both red fault

lamps will be lit.

Assistance in the event of

malfunction

CAUTION

Electric shocks can be fatal!

– Before working on possible live components, en-

sure the unit is disconnected from the power supply.

– Fault-clearance must only be undertaken by

authorized trained personnel.

– (Remote) resets may only be conducted by

authorized personnel.

▷

Faults may be cleared only using the measures

described below.