BCU 560, BCU 565 · Edition 02.16

13

Application > Examples of application

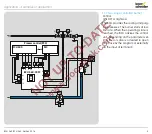

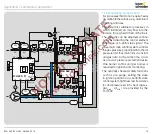

1 .1 .7 ON/OFF rotary impulse control for

burners up to 360 kW

For processes which require a turndown

of more than 10:1 and/or those which

require heavy circulation of the furnace

atmosphere to ensure a uniform tem-

perature, e.g. heat treatment furnaces

operating at low and medium tempera-

tures in the metallurgical industry.

With ON/OFF cyclic control, the capacity

supplied to the process is controlled by

means of a variable ratio of the operat-

ing time to the pause time. In this type of

control, the burner output pulse frequen-

cy always maintains full momentum and

results in maximum convection in the

furnace chamber, even with regulated

heating.

The pneumatic ratio control system con-

trols the gas pressure on the burner pro-

portionally to the air pressure and thus

maintains a constant air/gas ratio. At the

same time, it acts as a low air pressure

protection device.

The ignition and monitoring of the in-

dividual burners is ensured by burner

control unit BCU 560.

The centrally checked safety functions

such as pre-purge, tightness test, flow

detector and pressure switch check

(gas

min.

, gas

max.

, air

min.

) are provided

by the FCU 500.

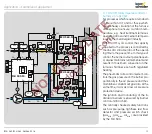

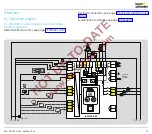

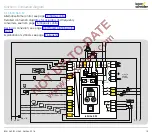

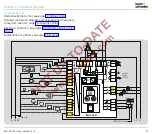

M

PZL

PZH

PZ

PZL

PDZ

TE

M

FCU 500..F0

µC

P

DG

DG

DG

VAS

VAS

VAS

VCG

VCG

VR..L

VR..L

DG

DG

DG

min

DG

max

49

15

13

14

50

45

47 48

58

>750°

p

u

/2

ϑ

1

46

2

3

DL

min

DL

Purge

BCU 560..F3

BCU 560..F3

STM