E-25

5. Align the paper guide plate (rear) with the line

marked in the bottom of the tray. Secure the

paper guide plate. (Four screws)

Note:

Depending on paper size, the positioning method

of the paper guide plate (rear) is different.

< B5/8.5”/16K >

Insert the paper guide plate (rear) into the hole

and press it towards the rear end of the hole until it

stops. Secure the plate with screws.

< A5/POST >

Insert the paper guide plate (rear) into the hole

and press it towards the front end of the hole until

it stops. Secure the plate with screws.

6. Place a sheet of paper as large as the paper size

you are setting in the bottom of the tray. Align the

paper guide plate (front) with the end of the

sheet.

Gap between the sheet and the paper guide plate

(front): 1mm or less

7. Tighten the two front screws. Remove the sheet

and tighten the two rear screws.

8. Align the end guide plate with the line marked in

the bottom of the tray and secure it. (Two screws)

9. Close the tray 3.

10. Turn ON the Main Power Switch.

11. Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the service manual.)

12. Select the LCC size setting function as follows:

System 2

→

LCT (Build-in) Size Settings.

13. Touch “Tray 3” and select the paper size that

was set for the tray 3.

14. Touch “END.”

15. Touch “Exit” on the Service Mode screen.

16. Turn OFF and ON the Main Power Switch.

Note:

When displayed the Service Mode screen, be sure

to turn off the main power after exiting the Service

Mode screen and wait for 10 seconds or more

before turning on.

17. Perform the same procedure for the tray 4.

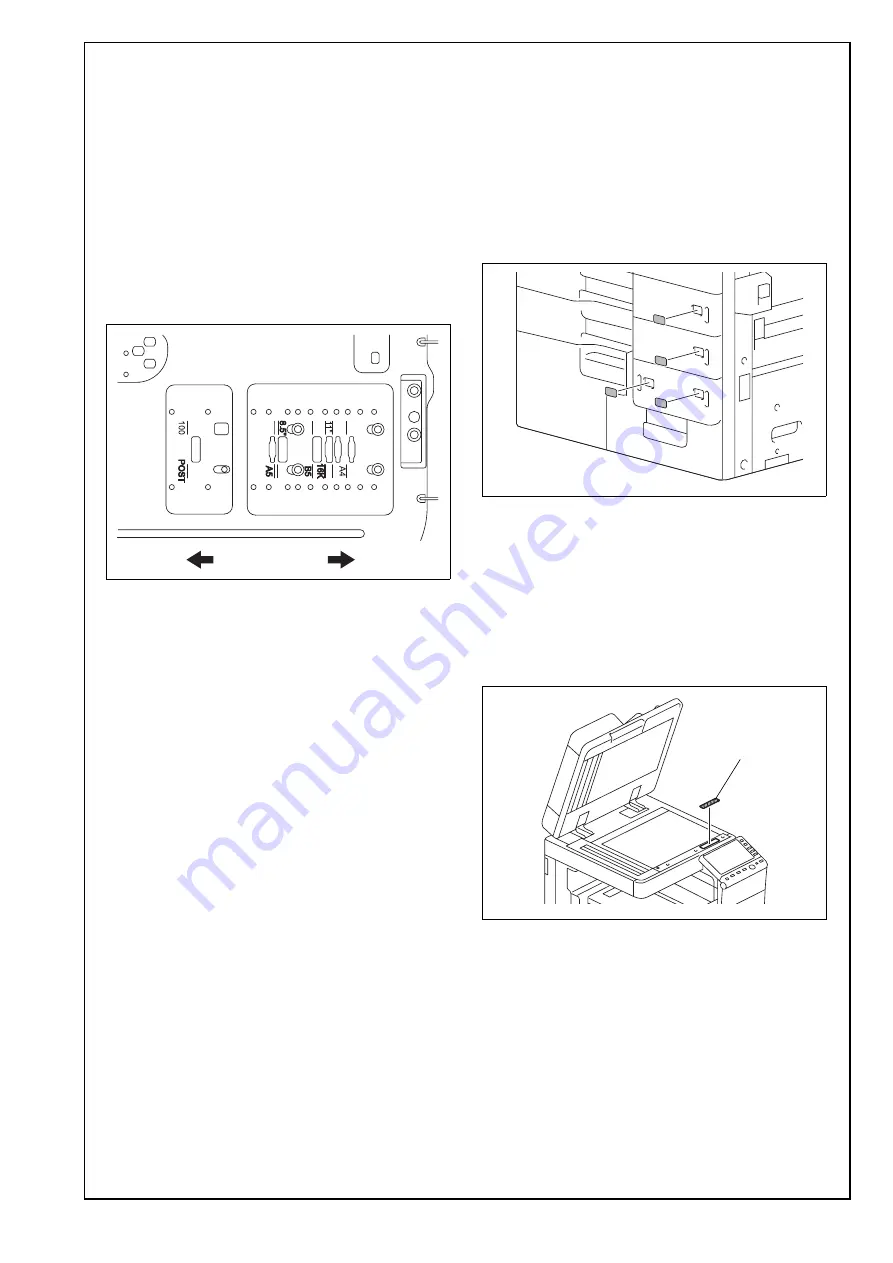

XXXI. Affixing the tray labels/paper size

labels

Affix the tray labels or paper size labels at the loca-

tions shown in the illustration.

Note:

If both are to be affixed, the tray labels should be

on the upper side and the paper size labels on the

lower side.

* For loading the paper as well as setting the paper

type, refer to the user’s guide.

XXXII. Affixing the label (Legal restrictions

on copying)

Affix the label (Legal restrictions on copying) to the

position shown below.

Note:

This step may not be performed depending on the

applicable marketing area.

A00JIXC227DB

Front

Rear

A2X0IXC043DA

A2X0IXE057DA

Label