55

* If the robot does not move, the following causes may be considered.

●

The KXR Power is not turned ON.

Check the battery mounting, connections and turn the robot power ON.

●

The Switch Harness is not connected correctly to the RCB-4.

Check the connection between the Switch Harness and the RCB-4HV.

* Note: Make sure the power switch is OFF before proceeding.

●

The battery is not charged.

If the robot does not move, even though the battery is correctly mounted and the power is turned

ON, then the battery may not be charged. Charge the battery.

●

The RCB-4 and the computer communication rates do not match.

Select "115200" for the COM communication rate in the Project Setting window.

Once the correct posture is confirmed, proceed to the Trim Adjustment process.

When the RAM button is clicked, the robot will assume this posture. If the robot does

not match this pose, then the origin setting is wrong. Retrace the origin setting steps to

determine and correct the part that is off track. Proceeding to set the Home Position

without confirming this posture can cause damage to the servo motors. Make sure that

the robot assumes this posture before continuing any further.

When given power, a servo may vibrate slightly (hunting); this is not a malfunction. Hunting

occurs when the stretch (holding force) is set at a high level to maintain neutral; when you

press down lightly and hold it still, hunting will stop. In the upright position of the sample

motion registered in the next step, stretch is set at a low level to help prevent hunting from

occurring. If hunting does occur depending on the posture of the robot (when the robot is

lifted up or shaken lightly, etc.), try holding the robot still.

The correct trim position is the pose shown in the diagram below. Press

the RAM button and confirm that the robot assumes this pose.

DANGER

Turtle

KXR-L4T

KXR-L4R

Rover

On the Rover type robot, the wheels

rotate briefly (for about 1.5 seconds)

right after the power is turned on.

When turning the power on, make sure to

lift up the robot so its wheels are off the

ground.

11. Adjust areas where the trim is out of alignment with reference to the image.

The trim position is an important base position for executing motions. In particular, if the left

and right legs are not in perfect alignment, walking, etc. in the sample motion will not pro-

ceed smoothly. When the trim is out of alignment, the overall motion will also be off, so

adjust the trim properly so that the robot stands perfectly upright.

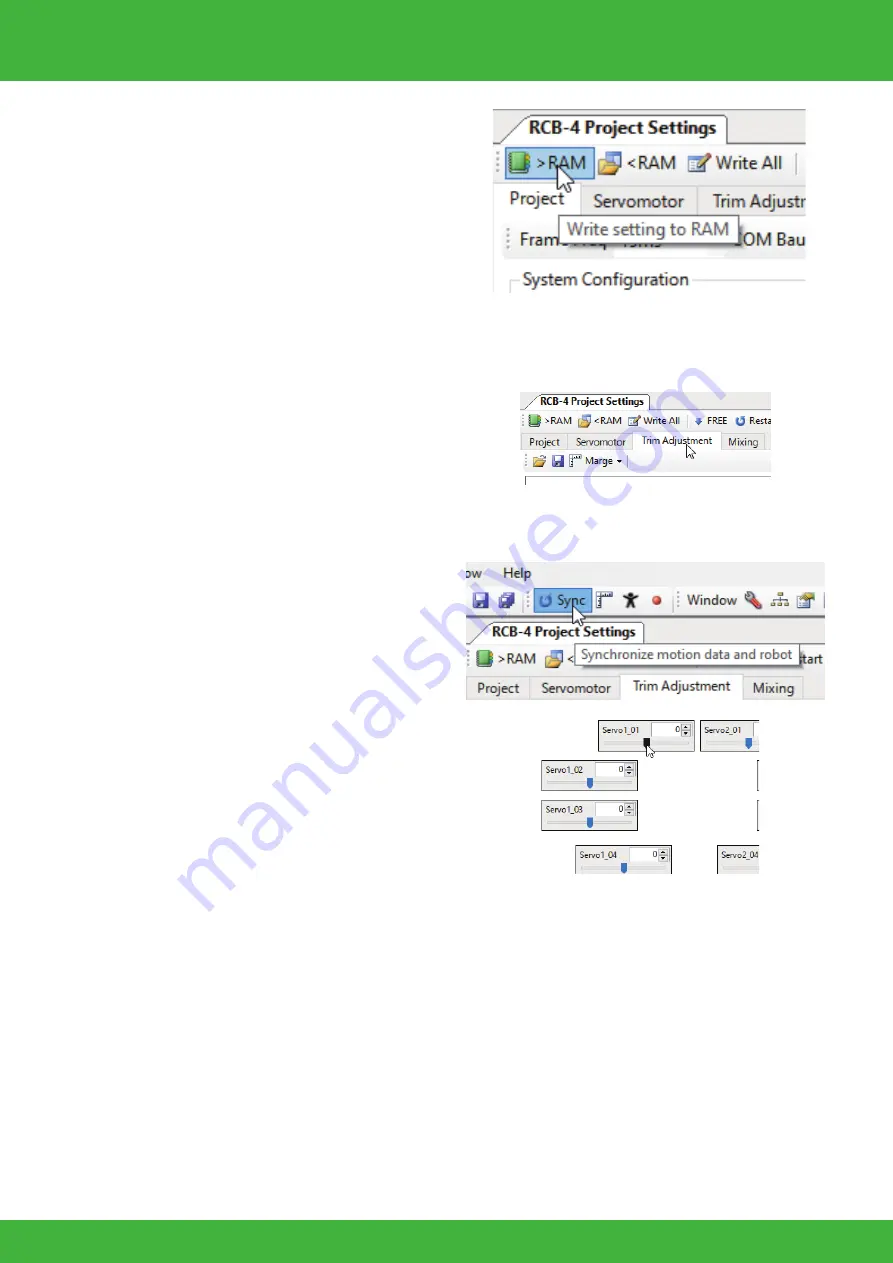

9.

Click the "Trim Adjustment" tab at the top of

the Project Setting window, to change

screens.

10. Press the "Sync" button in the toolbar

of the Main Window. If the color of the

button changes after pressing, it is

turned ON.

In the Sync state, the corresponding

servo motor operates on a real-time

basis by moving the HeartToHeart4

slide bar.

*The screen layout is an example for

reference purposes.

This applies when you run the robot for the first

time. When the servos are shipped from the factory,

there is no data loaded into them, thus the "RAM"

button needs to be clicked multiple times for initiali-

sation. Once initialised, pressing "RAM" once will be

enough to get robot moving.

8. Keep clicking on "RAM" button, al-

lowing 2 to 3 seconds between

each click until the robot slowly

moves to trim position.

Trim Adjustment 4