METHODS FOR TESTING FOR LEAKAGES INSIDE THE

SWIVEL JOINT

20-59

TESTING AND ADJUSTMENTS

METHODS FOR TESTING FOR LEAKAGES

INSIDE THE SWIVEL JOINT

H

Test conditions:

.

Engine: at working temperature.

.

Hydraulic oil: 45 ± 55ëC.

1. Functionality test

1 - When a lower actuator (blade, travel motor, travel

increment) is found to be defective, one of the

possible causes of failure is the swivel joint.

2 - In order to ascertain the cause of the defect it is

sufficient to by-pass the joint by connecting (using

a length of additional tubing) the input and output

tubes of the joint of the line to be checked.

If this corrects the defect, it is certainly due to the

swivel joint.

If the defect persists, it can be ascribed to other

causes, but definitely not to the swivel joint.

2. Looking for a defective seal

These controls are to be carried out only on tho-

se lines subjected to working pressures. The

drainage line is therefore not included in these

tests.

The test method consists of pressurising the line to be

checked and measuring any leakages from the adja-

cent lines according to the following tables:

PC12R-8

PC12R-8 PC15R-8

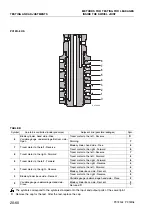

TABLE A

Symbol

Line to be controlled (under pressure)

Adjacent line (possible leakages)

Sym.

A

Travel motor to the right - Reverse

Travel motor to the left - Reverse

B

External leak (visible)

Ð

B

Travel motor to the left - Reverse

Travel motor to the right - Forward

C

Travel motor to the right - Reverse

A

C

Travel motor to the right - Forward

Travel motor to the left - Forward

D

Travel motor to the left - Reverse

B

D

Travel motor to the left - Forward

Blade cylinder, head side - Rise

E

Travel motor to the right - Forward

C

E

Blade cylinder, head side - Rise

Blade cylinder base side - Descent

F

Travel motor to the left - Forward

D

F

Blade cylinder base side - Descent

Descent Passage not used

]

G

Blade cylinder, head side - Rise

E

The symbols correspond to the symbols stamped onto the input and output ports of the swivel joint.

]

Remove the cap for the test. After the test, replace the cap.

RKP04820

G

Not used

F

Blade cylinder, base side - Descent

E

Blade cylinder, head side - Rise

D

Travel motor to the left - Forward

C

Travel motor to the right - Forward

B

Travel motor to the left - Reverse

A

Travel motor to the right - Reverse

Содержание PC12R-8 MISTRAL

Страница 1: ......

Страница 2: ...40 28 PC15R 8 ...

Страница 4: ...00 2 PC12R 8 PC15R 8 ...

Страница 17: ...GROUP 10 ...

Страница 18: ...40 28 PC15R 8 ...

Страница 30: ...10 12 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 32: ...10 14 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 34: ...10 16 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 36: ...10 18 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 38: ...10 20 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 40: ...10 22 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 42: ...10 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 44: ...10 26 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 79: ...10 61 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 130: ...10 112 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ......

Страница 133: ...GROUP 20 ...

Страница 134: ...40 28 PC15R 8 ...

Страница 149: ...PC15R 8 Standard value Permissible value Max 20 Max 30 2 Max 5 2 Max 5 2 Max 5 FOR THE MACHINE 20 15 PC12R 8 PC15R 8 ...

Страница 158: ...20 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 198: ......

Страница 199: ...GROUP 30 ...

Страница 200: ...40 28 PC15R 8 ...

Страница 283: ...GROUP 40 ...

Страница 284: ...40 28 PC15R 8 ...

Страница 295: ...HYDRAULIC PUMP PC12R 8 40 11 PC12R 8 PC15R 8 RKP00910 Z Vista Z 68 6 Nm 7 kgm 48 Nm 4 9 kgm View Z ...

Страница 298: ...40 14 PC12R 8 PC15R 8 RKP00131 Sezione A A 44 1w4 9 Nm 4 5w0 5 kgm 44 1w4 9 Nm 4 5w0 5 kgm Section A A ...

Страница 304: ...40 20 PC12R 8 PC15R 8 RKP00201 Sezione A A 44 1w4 9 Nm 4 5w0 5 kgm 44 1w4 9 Nm 4 5w0 5 kgm Section A A ...

Страница 317: ...40 33 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Страница 324: ......