-18-

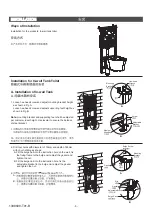

5. Unsnap the bracket and take it out from the tank.

5.

Bracket

Fastener

Fastener

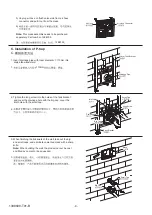

6. Hold fastener by hand as shown, pull the top of fastener

along the direction of arrow. Then remove fastener.

6.

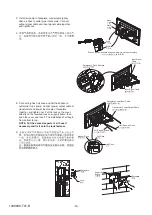

8. Remove discharge valve as shown and then take valve out

for cleaning.

8.

Outlet Valve

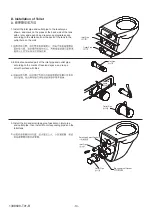

7. Pull discharge valve along the arrow direction as shown to

remove discharge valve.

7.

Outlet Valve

1338609-T01-B

Содержание VEIL K-20534T-S

Страница 26: ... 20 1338609 T01 B ...