ADJUSTMENT

10

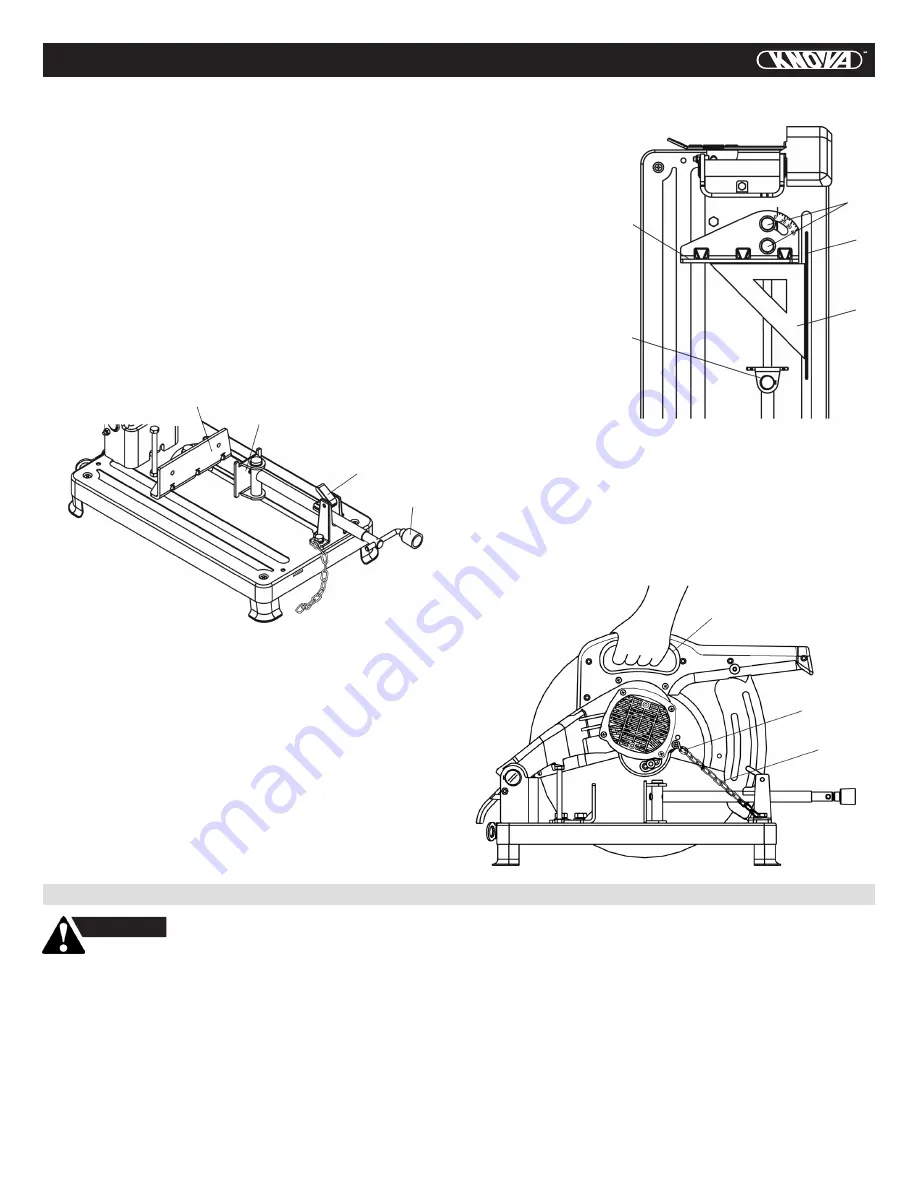

ADJUSTING THE VISE (FIG. G)

NOTE: The vise of your saw is used to secure the workpiece

during cutting operations.

1. Rotate the vise crank (1) counterclockwise to allow

enough room for the workpiece to fit between the vise

clamp (2) and the adjustable fence (3).

2. Position the workpiece between the vise clamp and the

adjustable fence. Turn the vise crank (1) clockwise to

clamp the workpiece securely.

3. The vise incorporates a quick release locking lever (4).

To use the quick release feature, lift up on the quick

release locking lever (4) and slide the vise clamp in or out

to the desired position.

4. When vise clamp is in desired location, flip the quick

release locking lever (4) down to engage the threads with

the threads of the vise. Begin to turn the vise crank (1)

clockwise to secure the workpiece within the vise.

Fig. G

1

4

2

3

ADJUSTING FOR ANGLE CUTTING (FIG. H)

1. Loosen the vise crank and back the vise clamp (3) away

from the adjustable fence (2).

2. Loosen the two bolts (1) of the adjustable fence with the

cutting wheel wrench.

3. Move the adjustable fence (2) to the desired angle

between 0 and 45 degrees.

4. Tighten the two bolts (1).

5. The vise clamp (3) will align itself automatically with the

angle of the workpiece when clamping a workpiece in

position.

NOTE: To check the squareness of the blade to the fence:

CARRYING YOUR CHOP SAW (FIG. I)

The

chop saw can be transported to any workplace

conveniently by:

1. Lowering the cutting arm to its lowest position and

securing in place by attaching the locking chain (1)

to the hook (2), located on the motor housing.

2. Transport the saw using the carrying handle (3) located

above the motor.

1. Loosen the vise crank and back the vise clamp (3)

from the adjustable fence (2).

2. Loosen

the two

bolts (1) on the

adjustable fence

with the cutting

wheel wrench.

3. Lower the cutting

arm down until

the wheel (4) is

below the base.

4. Place a square

(5) against the

wheel and adjust

the fence against

the square.

5. Raise the cutting

arm up and lock

the fence into

position.

Fig. H

5

4

1

2

3

Fig. I

3

2

1

OPERATION

WARNING

Never connect the plug to the power

source outlet until all installations and adjustments

are completed and you have read and understood

the safety and operational instructions.

ON/OFF SWITCH (FIG. J)

The

ON/OFF trigger switch (1) is located on the handle

position of the cutting arm.

1. Turn the chop saw ON by depressing the trigger switch (1).

2. To turn off, release the trigger switch (1).

NOTE: Make the ON/OFF switch childproof. Insert a

padlock or chain with padlock through the hole (3) in the

trigger switch to lock the switch, preventing children and

other unauthorized users from turning the machine on.

LOCK-ON BUTTON (FIG. J)

1.

To

engage the lock-on feature, depress the trigger switch (1),

and simultaneously push in the lock-on button (2) located

on the side of the handle. Release the switch and the tool

will run continuously.

2. To disengage the lock-on feature, depress the trigger

switch and release.

Содержание KN CS-3555R

Страница 1: ...KN CS 3555R Chop saw14 Cortadora para metal 355 6 mm...

Страница 16: ...15 SCHEMATIC KN CS 3555R Chop saw 14 Cortadora para metal 355 6 mm...

Страница 32: ...ESQUEMA 31 KN CS 3555R Chop saw 14 Cortadora para metal 355 6 mm...

Страница 33: ...NOTE NOTAS 32...

Страница 34: ...NOTE NOTAS 33...

Страница 35: ...NOTE NOTAS 34...

Страница 36: ...www knova com mx...