9

Knorr-Bremse Group

PD-203-360

Doc. No. Y250908 (EN - Rev. 001)

September 2016

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring.

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

KB4TA/KB4TA D System Components

C o m m e r c i a l V e h i c l e S y s t e m s

Wheel Speed Sensor

Function:

The wheel speed sensor is mounted, using a spring-

loaded bush, in a housing on the axle in such a position

that the end of the sensor is as close as possible to

the teeth of the sensing ring. The wheel speed sensor

contains an internal permanent magnet whose magnetic

field extends a short distance beyond the end of the

sensor case. A coil is wrapped around a soft iron core,

which is attached to the magnet. This coil is connected

to the output cable.

When a wheel rotates, the teeth of the sensing ring pass

in turn through the magnetic field of the sensor magnet

and disturb the field thereby creating an induced

voltage in the sensor coil. This voltage is monitored by the

KB4TA/KB4TA D module via the output cable. The

voltage generated takes the form of a sine wave with

both the voltage and frequency increasing as the

rotational speed of the wheel increases. The module

requires a minimum voltage before it recognises the

signal from the wheel speed sensor and thereafter it

uses the frequency of the signal to monitor the rotational

speed of the wheel. The voltage generated by the coil is

dependent not only on the rotational speed of the wheel

but also on the gap between the end of the wheel speed

sensor and the teeth of the sensing ring: the larger the

gap the lower the generated voltage. It is important,

therefore, that the gap is kept as small as possible to

ensure that sufficient voltage is generated to maintain

low speed ABS performance.

Technical data:

Operating temperature range:

• Speed sensor: . . . . . . . . . . . . . . -40 °C to +160 °C

• Cable: . . . . . . . . . . . . . . . . . . . . -40 °C to +180 °C

• Plug: . . . . . . . . . . . . . . . . . . . . . -40 °C to +80 °C

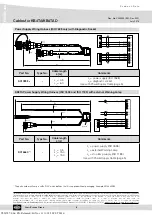

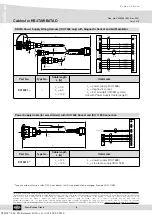

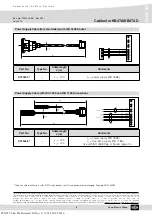

90 ° Speed Sensor

Straight Speed Sensor

Sensor Clamping Sleeve

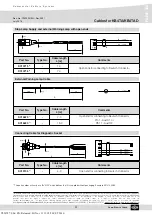

Installation instruction

Typically, the wheel speed sensor is installed in a

mounting block that is welded to the axle housing.

Wheel speed sensors are protected by a stainless steel

sheath. They are designed to be used with a clamping

sleeve (sometimes referred to as a “retainer bushing”,

“friction sleeve” or “clip”). The clamping sleeve provides

a friction fit between the mounting block bore and the

sensor.

A proper sensor installation is critical for correct ABS

operation.

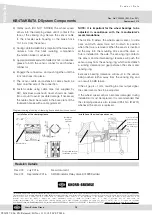

1) For increased corrosion protection it is recommended

that a high temperature rated silicon or lithium based

grease be applied to the interior of the mounting

block, the wheel speed sensor, and to the new

clamping sleeve. Recommended grease - Part No.

I

90693.

2) Push the new clamping sleeve fully into the block,

with the retaining tabs toward the inside of the

vehicle. Please note that wheel speed sensors must

use the correct clamping sleeve. Failure to do so may

result in reduced retention force, allowing sensor

movement resulting in ABS failure.

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: