—

29

—

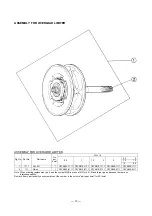

WLL (t)

Fig.

No.

Part No.

Part name

No.

per

hoist

0.5 1 1.5 3 2

1

1001

Top hook set

1

C1FA005-1001 C1FA010-1001 C2FA015-1001

————————

C3BA0200-1001

2

1071

Hook latch assembly

1

C3BA005-1071 C1FA005-1071 C1FA010-1071

————————

C1FA015-1071

*

Suspender for TSP005 1

T5PC005-9004 ——————————————————————————————————

*

Suspender for TSG010 1

T5GC010-9004 ————————————————————————

3

* Suspender

1 ————————————————

T5GC020-9004 ———————— T5GC020-9004

4

163

Top

pin

1

C3BA005-9163

C3BA010-9163 C3BA015-9163 C3BA020-9163

5

198

Split pin

1

J1PW01-030018

J1PW01-030025

6

1021

Bottom hook set

1

C3BA005-1021 C3BA010-1021 C3BA015-1021

————————

C3BA020-1021

7

1071

Hook latch assembly

1

C3BA005-1071 C1FA005-1071 C1FA010-1071

————————

C1FA015-1071

8

41

Chain pin

1

C3BA005-9041

C3BA010-9041 C3BA015-9041

————————

C3BA020-9041

9

49

Slotted nut

1

C3BA005-9049

C3BA010-9049 C3BA010-9049

————————

C3BA020-9049

10

96

Split pin

1

J1PW01-016010

J1PW01-020012

J1PW01-020012

————————

J1PW01-020014

11

5101 (1)

Side plate A assembly

1

C3BA005-5101

C3BA010-5101

C3BA015-5101

C3BA020-5101

12

806

Name plate F

1

C3BA005-9806

13

5102 (1)

Side plate B assembly

1

C3BA005-5102

C3BA005-5102

C3BA015-5102

C3BA025-5102

14

116

Load

sheave

1

C3BA005-9116

C3BA010-9116 C3BA015-9116 C3BA020-9116

15

140

Ball bearing

1

J1GR002-06006

J1GR002-06007

16

145

Ball bearing

1

J1GR002-06005

J1GR002-06006

17

111

(1)

Pinion

1

C3BA005-9111

C3BA010-9111 C3BA015-9111 C3BA020-9111

18

130

Roller

bearing

1

C3BA005-9130

C3BA020-9130

19

118

Snap ring

1

C3BA005-9118

C3BA020-9118

20

161

Guide

roller

2

C3BA005-9161 C3BA010-9161 C3BA015-9161

C3BA020-9161

21

162

Stripper

1

C3BA005-9162

C3BA010-9162 C3BA015-9162 C3BA020-9162

22

176

Anchorage

1

C3BA005-9176

C3BA010-9176 C3BA015-9176 C3BA020-9176

23

177

Stopper

pin

1

C3BA005-9177

C3BA010-9177 C3BA015-9177 C3BA020-9177

24

196

Splint pin

1

J1PW01-020012

J1PW01-025015

25

114

Load

gear

1

C3BA005-9114

C3BA010-9114 C3BA015-9114 C3BA020-9114

26

117

Snap ring

1

J1SS000-00022

J1SS000-00028

C3BA005-5122

C3BA010-5122 C3BA015-5122 C3BA020-5122

27

5112 (1)

Gear #2 assembly

(3)

1 2

2

2

28

135

Ball bearing

1

J1GR002-6200

J1GR002-06201

29

6103

Gear case assembly

1

C3BA005-6103

C3BA010-6103

C3BA015-6103

C3BA020-6103

30

800 (1)

Name plate B with rivets

1

C3BG005-9800 C3BG010-9800 C3BG015-9800 ———————— C3BG020-9800

31

181

Nut

3

J1NA001-20080

J1NA001-20100

32

186

Spring washer

3

J1WS011-20080

J1WS011-20100

33

5179

Pawl spring set (A & B) (2)

1

C3BA005-5179

34

155

Pawl

1

C3BA005-9155

35

157

Snap ring

1

J1SS000-00010

36

153 (1)

Friction disc

1

C3BA005-9153

C3BA020-9153

37

151 (1)

Friction plate

2

C3BA005-9151

C3BA020-9151

38

152 (1)

Ratchet disc

1

C3BA005-9152

C3BA005-9152

39

154 (1)

Bushing

1

C3BA005-9154

C3BA020-9154

40

115 (1)

Hand wheel

1

C3BA005-9115

C3BA015-9115

C3BA020-9115

41

159

Wheel stopper

1

C1FA005-9159

C1FA015-9159

42

167

Wheel stopper pin

1

C3BA005-9167

43

199

Split pin

1

J1PW01-020008

44

5171

Wheel cover assembly

1 C3BA005-5171

C3BA015-5171 C3BA020-5171

45

182

Nut

3

J1NA001-20080

46

187

Spring washer

3

J1WS011-20080

47

841

Load chain

1

K7UN050-00000

K7UN063-00000

K7UN071-00000

K7UN080-00000

48

842

Hand chain

1

K7NA050-00000

49

931

Warning tag

1

ER1BS9686

50

45

Chain stopper link

1

L5BA032-9045

51

164

End pin

1 ——————————————————————————————————————————————

52

197

Split pin

1

——————————————————————————————————————————————

53

176

Cross guide

1

——————————————————————————————————————————————

115

158

Washer

1

C3BG005-9158

Notes: * See trolley part lists.

(1) When ordering replacement part, use the symbol M3B in place of M3 for 2.5t, 5t and larger types, because there are no interchangeability.

(2) Pawl spring A and B must be used as a set.

(3) Each number in "WLL" columns is No. per hoist.

Remark: Every part quantity becomes twice of the number in the column "parts per hoist" for 20t hoist.