—

23

—

Assembly procedures

Remarks

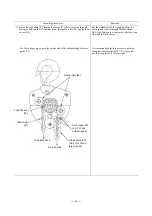

15. Apply machine oil to the pawl pin (in side plate A [11]) and join the pawl

spring A, B [33] and the pawl [34] respectively to it. Fix them with a snap

ring [35].

Mark sure the pawl spring is touching the pawl

and the snap ring is completely set at the

bottom of the groove.

16. Put the friction disc [36] to the pinion [17] shaft (while turning the pawl [34]

counterclockwise).

17. Wipe our any dirt on the friction disc [36], friction plates [37] and both sides

of the ratchet disc [38] and check if the oil of the bushing [39] (bushing with

containing oil) is applied enough. Then place the friction plate, bushing,

ratchet disc and friction plate respectively on the friction disc. (Make sure

that the pawl meshes with the ratchet disc properly)

NEVER

apply oil since the brake is `dry-type’.

Wipe out thoroughly any oil and dirt on the

brake. The gear of the ratchet disc should point

at the pawl.

Otherwise, the hand wheel cannot be

assembled later.

However, in case the bushing does not have oil

inside, soak it in tarbin oil for a day. Install it

in without wiping the oil.

Make sure that the pawl meshes with the

ratchet disc properly.

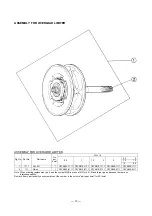

18. Wipe out the dirt of the hand wheel [40] and apply machine oil to the

threaded part of it. Screw it in the pinion [17] shaft all the way down.

19. Place the wheel stopper [41] on the head of the pinion [17], insert the wheel

stopper pin [42] and fix it with a split pin [43].

ALWAYS

bend the split pin securely after

inserting into the wheel stopper pin.

Pawl [34]

Snap ring [35]

Ratchet

disc [38]

Bushing [39]

Friction plate [37]

Pawl spring [33]

WARNING