ADJUSTMENTS & OPERATION

ADJUSTING OUTFEED ROLLER continued...

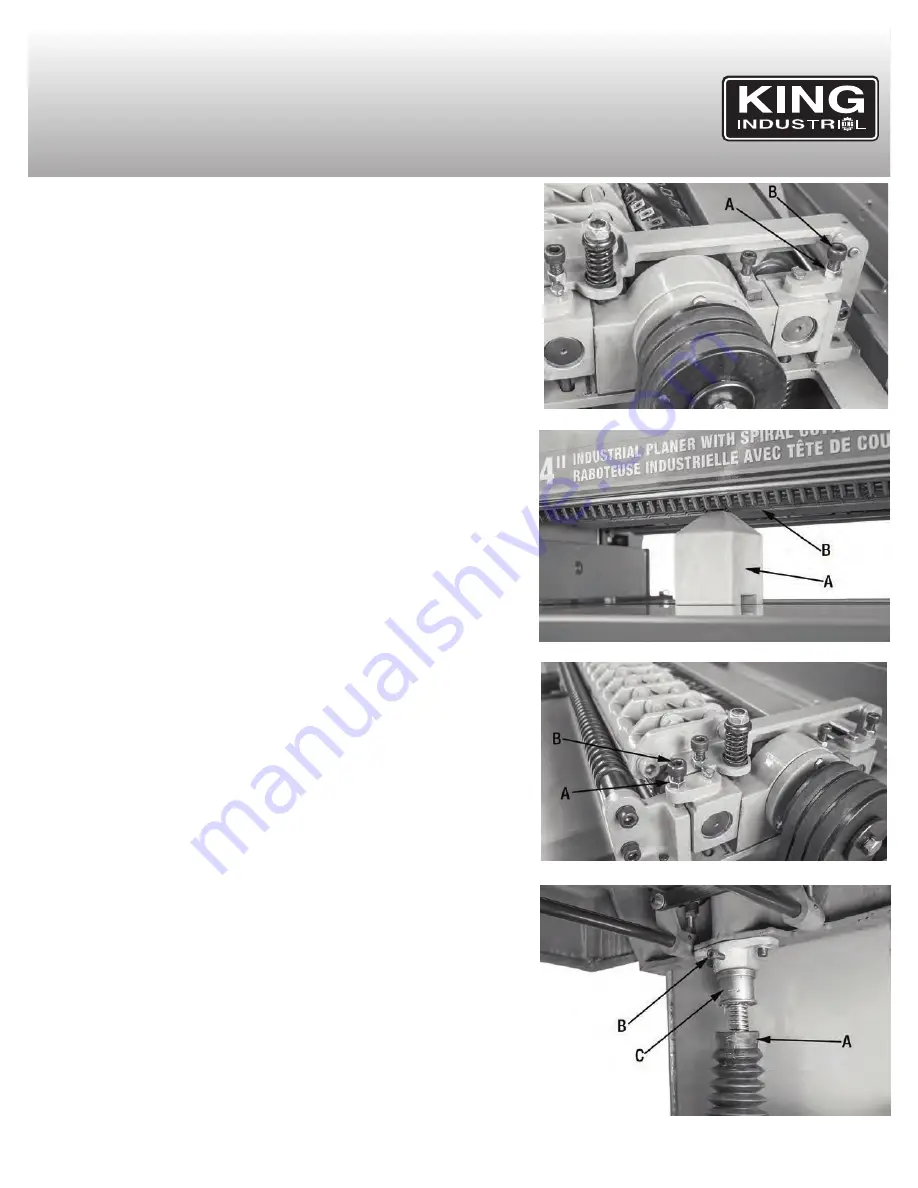

5. If the outfeed roller needs to be adjusted: Loosen the hex. nut (A) Fig.21, and

rotate the adjustment cap screw (B) using a hex. key until the outfeed roller is

just touching the top of the gauge block at one end of the table. Retighten the

hex. nut once adjustment has been made. Repeat this step at the other end of

the outfeed roller.

ADJUSTING INFEED ROLLER

The infeed roller feeds the stock into the machine as the surface is planed. The

infeed roller should be set at 0.040” below the “cutting circle”, to ensure it can feed

the stock without slipping.

To check and adjust the infeed roller:

1. Disconnect the Planer from the power source.

2. Rotate the cutterhead so that one of the cutter inserts is set at its lowest point

(you can use the drive belts to turn the cutterhead). Place the gauge block (A)

Fig.15 underneath directly underneath the cutter insert.

3. Place a 0.040” feeler gauge (B) Fig.15 on top of the gauge block, and raise the

table until the feeler gauge is touching the cutter insert set at its lowest point.

NOTE:

Don’t move the table until the adjustment has been completed. If the table

has been moved, start again at Step 1.

4. Move the gauge block (A) Fig.22 directly underneath the infeed roller (B). The

infeed roller should just touch the top of the gauge block.

5. If the infeed roller needs to be adjusted: Loosen hex. nut (A) Fig.23, and rotate the

adjustment cap screw (B) using a hex. key until the infeed roller is just

touching the top of the gauge block at one end of the table. Retighten the lock nut

once adjustment has been made. Repeat this step at the other end of the

infeed roller.

LEVELING THE TAbLE

The table is set parallel to the cutterhead from the factory, and should not need to

be adjusted. However, with time and use, it may need to be adjusted.

To check and adjust the table:

1. Rotate the cutterhead so that one of the cutter inserts is set at its lowest point (you

can use the drive belts to turn the cutterhead). Place the gauge block

directly underneath the cutter insert.

2. Raise the table until the gauge block is just touching the cutter insert.

3. Move the gauge block to the opposite side of the table. The distance between

the cutter inserts on both sides of the table should be identical.

If the table needs to be adjusted:

4. Raise the table so you are able to access the rubber boots (A) Fig.24 which

cover the table columns. Carefully clip the cable tie holding up the boot, and

lower one of the rubber boots to expose the cap screw (B) and adjustment

sleeve (C).

5. Loosen the cap screw (B), and rotate the adjustment sleeve (C) until the table is

parallel with the cutter insert set at its lowest point. Repeat this adjustment for

the other side of the table.

FIGURE 21

FIGURE 22

FIGURE 23

FIGURE 24