Introduction 1

Man-1453 Rev.01

Sigma ZXT SI Product Manual

1

Section 1

Introduction

The Sigma-SI Status Units are designed in accordance with European standard EN12094-1 Fixed fire-fighting sys-

tems - Components for gas extinguishing systems - Part 1: Requirements and test methods for electrical automatic

control and delay devices.

The Sigma ZXT SI Status Units are designed to extend the indications and some controls of Sigma ZXT extinguis-

hant control panels to other locations within the fire protection system. They can be introduced to make operation

of the system more practical, within areas that have multiple access points (or doors). A maximum of seven status

units may be connected to each control panel extinguishant area.

All units connect to a two wire data communications bus and are powered by the Auxiliary 24V DC output of com-

patible, extinguishant Control Panels.

The Sigma ZXT SI range consists of:

Supporting Documentation

In conjunction with this manual, it is strongly advised that Sigma ZXT Product Manual is read and understood.

Sigma ZXT Installation Manual

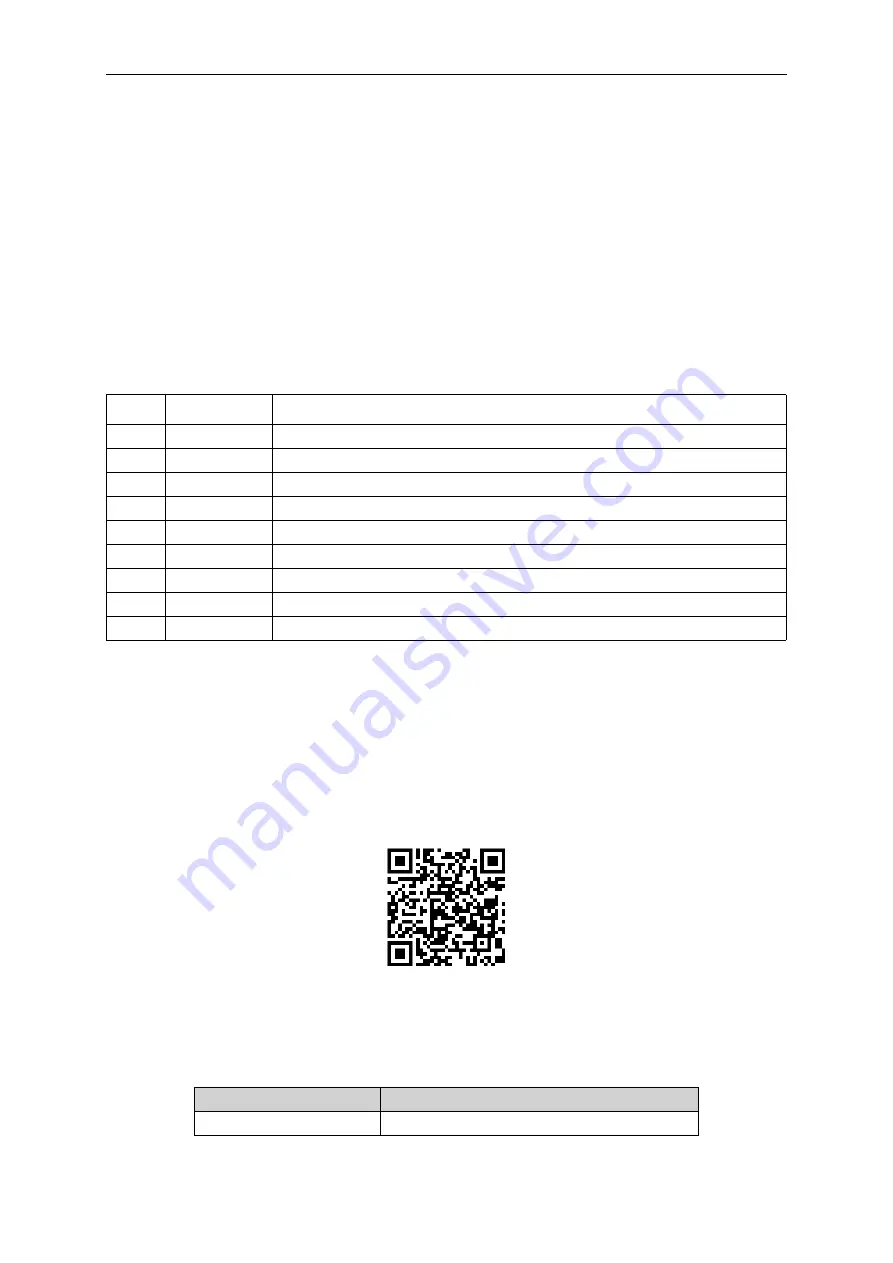

Using the a smart phone or device, the Manual can be accessed by working with the QR code below:

Should you be unable to work with QR codes the Manual can be obtained by visiting the following website pages:

Item

Product Code

Description

1.

K921000M8

6 Lamp Status Unit

2.

K921010M8

6 Lamp Status Unit with Manual Release

3.

K921100M8

6 Lamp Status Unit with Mode Select

4.

K921110M8

6 Lamp Status Unit with Mode Select & Manual Release

5.

K921113M8

10 Lamp Status Unit with Buzzer, Mode Select & Manual Release

6.

W921000W8

Weatherproof 6 Lamp Status Unit

7.

W921100W8

Weatherproof 6 Lamp Status Unit with Mode Select

8.

W921110W8

Weatherproof 6 Lamp Status Unit with Mode Select & Manual Release

9.

W921113W8

Weatherproof 10 Lamp Status Unit with Buzzer, Mode Select & Manual Release

Installation Manual

Manual Variant

Website

Installation Manual

http://www.kentec.co.uk/manuals/man-1451EN.pdf