Section/page:12.2

Trouble shooting/error codes

KEN DW 412

Subject to alterations

17/9/2013

NB! Remedying an error that requires the use of tools to remove the

machine cover plates may only be carried out by specially trained,

technical staff.

Display/error #20 - #35

Cause

Remedial action

#20 WATER PRESSURE TOO LOW

The water filling has lastet too long

according to the programmed time,

which corresponds to a water pres-

sure of 1-2 bar in the connection to

the machine. This pressure is too

low to ensure an acceptable rinse.

1. Stand-pipe is not in proper

position; water is running out of

the tank.

2. Strainer in water softener is

choked up.

3. Strainer on the inlet of the

solenoid valve is clogged.

4. Too low pressure in installation.

Stand-pipe to be placed in the right

position.

To be cleaned.

To be cleaned.

To be repaired, a pressure increase

pump may be installed.

#25 MISSING WATER PRESSURE

The water filling has lastet too long

according to the programmed time,

which corresponds to a water pres-

sure of 0-1 bar in the connection to

the machine. The rinse system is

unable to function at this pressure.

1. Stop cock in installation closed.

2. Verify that no sequenses 1,2,3

and 4 at #20 are present.

3. Defective solenoid valve.

4. Missing electrical connection to

solenoid valve.

5. Missing signal from level sensor

in wash tank.

Open the stop cock.

See 1 - 2 - 3 - 4 at #20.

To be replaced.

Repair connection to solenoid valve.

Repair connection to level sensor.

Adjust level sensor if necessary.

#30 SLOW HEATING WASH TANK

The heating element in wash tank

has been coupled in for longer than

a normal period, without reaching

the correct wash temperature.

1. Defective heating element VL1.

To be replaced.

#31 SLOW HEATING RINSE TANK

The heating element in rinse tank

has been coupled in for longer than

a normal period, without reaching

the correct rinse temperature.

1. Defective heating element VL2.

To be replaced.

#35 NO HEATING WASH TANK

The heating element in wash tank

has been coupled, without reaching

the correct wash temperature.

1. Automatic cut-out T1 disconnected.

(placed under the machine, right

side)

2. Defective heating element VL1.

3. Defective contactor C1.

4. Missing connection from output

Activate output and measure wire

to C1.

Try max. once to reconnect.

(The cause of the cut-out must be

found)

To be replaced.

To be replaced.

Activate output and measure wire

connection.

Содержание 59.480

Страница 2: ......

Страница 9: ...KEN DW 410 Section page 3 1 Subject to alterations 17 9 2013 Technical description Dimensional sketch ...

Страница 33: ......

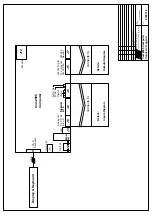

Страница 40: ...KEN DW 412 Section page 17 1 Subject to alterations 17 9 2013 Diagrams ...