EN

1502937-00

- 71 -

NOTE

If necessary, it is also useful to change the dust collection container

during this procedure.

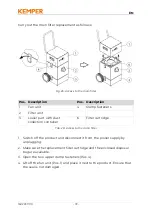

7.2.3

Main filter change

The life of the filter inserts depends on the type and amount of deposited

particles.

As the dust accumulation in the filter increases, its flow resistance

increases and the extraction capacity of the product decreases.

Even in the case of products with an automatic filter cleaning system (if

present), deposits can reduce the flow resistance.

A filter change is required.

WARNING

Health hazards caused by welding fume particles

Inhalation of welding fume particles, especially welding fume particles

from welding processes on alloyed steels, can damage your health as

they are ‘respirable’. Skin contact with welding fume particles can cause

skin irritation in sensitive individuals.

To avoid contact with and inhalation of these dust particles, wear

disposable overalls, protective goggles, gloves and a suitable Class FFP2

respiratory protection filter mask in accordance with EN 149.

NOTE

During the work described in the following section, pay particular

attention to the seal on the main filter. Only an undamaged seal allows

the product to achieve a high filter efficiency. Main filters with a damaged

seal must therefore be replaced every time.

NOTE

Please also refer to the “Installation” and “Use” chapters for the following

stages.

•

Only original replacement filters, because they guarantee the

necessary filter efficiency and are matched to the product and its

performance characteristics.

Содержание 63200

Страница 2: ...Typenschild einkleben ...

Страница 476: ......