18

SERVICE

INTERVAL

ACTION

Oil

Exchange after 10 h

Thereafter every 50 h

or once a year

Oil Change

•

Use hydraulic oil ISO 32 or 46

•

Draining the tank is done by removing

the drain-plug under the tank.

•

Fill through the filler plug on top.

Bolts and nuts

Check regularly, preferably before each use

Check and retighten all bolts and nuts

Moving parts

Regularly

Lubricate moving parts on a regular basis

Chainsaw

Regularly

Check the condition of the following parts:

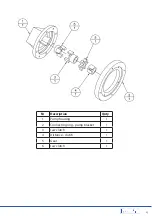

Gear: check for abrasion and/or cracks

Guide bar: Check for abrasion.

Chain: The cutting links must be kept sharp

for the machine to cut efficiently. Sharpens if

requires.

TROUBLESHOOTING

ERROR

PROBABLE CAUSE

ACTION

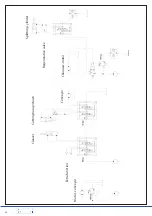

The piston is not moving

forward

Low or no pressure in the system

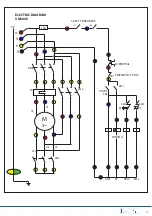

The engine rotates the wrong way

Check oil pressure and level. check if there’s

a leak age in the system.

Check the engine rotation and reverse if

requires

The machine doesn’t start

Fault with the power source

The machine is not correctly plugged

Check the power source

Check and plug the machine correctly.

The machine don’t have

the power

Low or no pressure in the system

Check if there’s leakage in the system.

Check all couplings and hydralic hoses.

Chainsaw is not working

The machine is not plug

Check and connect.

The infeed conveyor

doesn’t move forward

The belt is not correctly tightened

or broken

Check the conveyor belt. Replace or tighten

if necessary