Page 28

DOC0945 (22 August 2022 15:28)

www.keit.co.uk

Back to Table of Contents

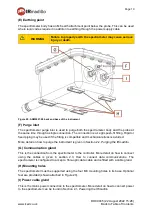

Figure 26: Fitting a flanged probe to process pipework

Once the spectrometer is aligned with the port, fit appropriate bolts as specified in the relevant

standard, and tighten in stages in the order shown below.

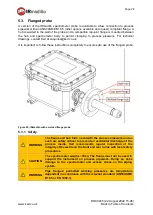

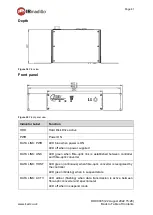

Figure 27: Front view of lap-joint flange, hub and bolt holes. Tighten bolts in steps in order 1-2-3-4 to

ensure even compression of the gasket

Ensure that the bolts are sufficiently tight to prevent a leak from your pipework.

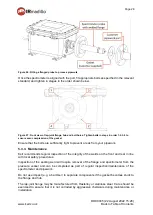

5.3.3. Maintenance

Keit recommends regular inspection of the integrity of the welds on the front and rear in line

with local safety procedures.

Inspection of the sealing weld will require removal of the flange and spectrometer from the

pressure vessel and can be completed as part of regular inspection/maintenance of the

spectrometer and pipework.

Do not use impact (e.g. a hammer) to separate components if the gasket becomes stuck to

the flange and hub.

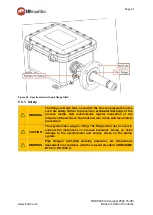

The lap-joint flange may be manufactured from Hastelloy or stainless steel. Care should be

exercised to ensure that it is not corroded by aggressive chemicals during maintenance or

installation.