INSTALLATION INSTRUCTIONS

R−410A, Two−Stage Split System Air Conditioner

421 01 6002 01

9

AIRFLOW SELECTION

Two−stage compressor operation requires two different

indoor airflow settings for proper operation. This outdoor

unit is designed for use only with an indoor blower that can

be configured for separate low−stage and high−stage

airflow (CFM) levels. Refer to Product Specifications

Sheets for recommended low−stage and high−stage

indoor airflow values. Refer to indoor unit Installation

Instructions to set the indoor blower for the proper

low−stage and high−stage airflow values.

NOTE: Optimal comfort, efficiency, and reliability will only

be achieved when the indoor airflow is properly set for

both low−stage and high−stage operation.

START−UP PROCEDURE

1.

Set indoor thermostat selector switch to OFF.

2.

Turn ON all electrical disconnect devices.

3.

Unit has a crankcase heater. Energize the heater and

wait 24 hours before proceeding.

4.

Set indoor thermostat at desired temperature. Be

sure setpoint is below indoor ambient temperature or

thermostat will not call for cooling.

5.

Set indoor thermostat selector switch to COOL.

Operate unit for minimum 25 minutes, then check the

system refrigerant charge.

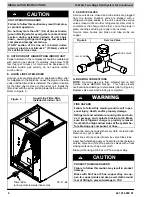

REFRIGERANT CHARGE

NOTE: Charge in High−Stage only.

Outdoor units are shipped with a refrigerant charge to

match a specific indoor coil and 15 feet (4.6m) of

refrigerant line. If shorter or longer refrigerant lines or a

different indoor coil are used, the charge will have to be

adjusted.

For different line lengths, add or remove charge based on

0.6 ounces (17g) charge per foot (305mm) of difference.

For example, a 25 foot (7.6m) line set is 10 feet (3m)

longer than the specified 15 feet (4.6m). Add 0.6 ounces

(17g) charge for each of the extra 10 feet (3m):

10 x 0.6 = 6.0 ounces additional charge

(3m x 17g = 51g additional charge)

This outdoor unit is designed for use only with indoor coils

that utilize a TXV refrigerant metering device. With an

indoor TXV, use the subcooling method to make final

charge adjustments:

NOTE: Only use subcooling charging method when

outdoor ambient temperature is between 70

F and 100

F

(21

C and 38

C)

indoor temperature is between 70

and 80

F (21

C and

27

C)

line set is less that 80 feet (24.4m).

1.

Operate unit a minimum of 25 minutes in

high−stage before checking charge.

NOTE: Outdoor unit has a 2−speed fan motor.

Motor will operate in low speed when outdoor

ambient temperature is below 82

°

F (28

C). Pull

one of the yellow low voltage wires off the fan

control and the unit will default to high speed fan for

servicing. Reconnect wire after servicing.

2.

Measure liquid service valve pressure by attaching

an accurate gauge to service port.

3.

Measure liquid line temperature by attaching an

accurate thermistor type sensor or electronic

thermometer to liquid line near outdoor coil.

4.

Refer to unit rating plate for required subcooling

temperature.

5.

Refer to Figure 11. Find the required liquid line

temperature where the rating plate subcooling

temperature intersects measured liquid service

valve pressure.

6.

If the measured liquid line temperature is higher

than the chart number, add refrigerant to lower the

measured temperature.

NOTE: When adding refrigerant, charge in liquid form,

using a flow restricting device, into the suction port. If the

measured liquid line temperature is lower than the chart

number, reclaim refrigerant to raise the measured

temperature.

Tolerance is

3

°

F (

1.7

°C)

.