A 9 Maintenance

Repairs and servicing work on the

electrical part of this equipment must

only be undertaken by experts or by

persons trained in our factory who are

aware of the safety regulations. Disconnect

the mains plug from the power supply or

switch off the disconnecting switch before

opening any part of the equipment.

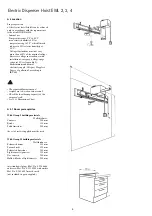

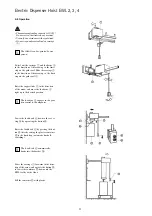

9.1 Maintenance – monthly.

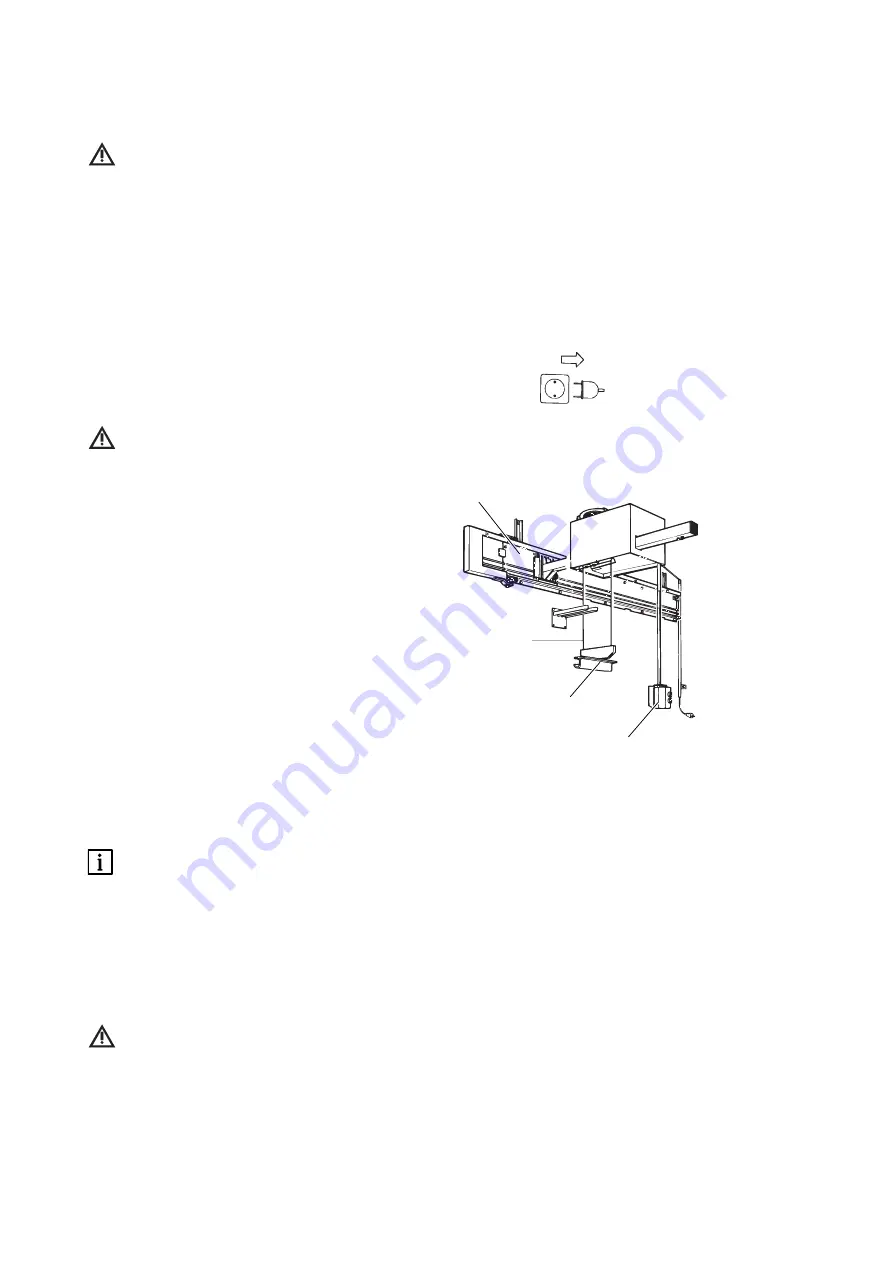

Check the reel-in track and steel rope

4

for anchorage.-examine electricity supply

cables for wear and damage.

If there are any breaks in the strands

of the steel rope

4

, then the rope

must be changed for safety reasons!

9.2 Maintenance – annually.

Check the anchorage of the guide rail 1 on

the wall.

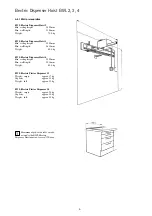

9.3 Annual function checks:

• Downwards switch-off

Press button

2

“AB“ – switch-off must

follow when the load hook

3

is

4 - 6 cm above the floor.

• Upwards switch-off

Press button

1

“AUF“, - check if the

upwards switch-off functions.

• Move the Silolift up and down under load

no unusual sounds, such as screeching or

similar, should be audible.

Points 9.1 - 9.3 must be documen-

ted, and kept with a “Maintenance

and Function Checks Record“ for the

Silolift.

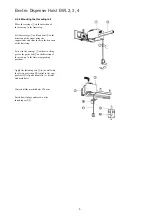

Cleaning

Wipe away any dirt on the outside with a

damp cloth.

When cleaning , prevent any ingress

of water into the unit.

13

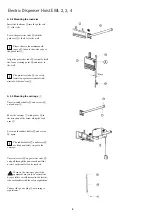

Electric Dispenser Hoist EWL 2, 3, 4

1

4

3

2

Содержание EWL 2

Страница 1: ...Operating instructions Electric Dispenser Hoist EWL 2 3 4 Always on the safe side...

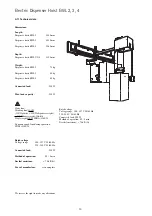

Страница 19: ...17 Electric Dispenser Hoist EWL 2 3 4 2322 mm 2480 mm 2137 mm 2540 mm SK 01 574...

Страница 21: ...19 Electric Dispenser Hoist EWL 2 3 4...

Страница 23: ...21 Electric Dispenser Hoist EWL 2 3 4...