16

English

5.905-945.0 Rev. 00 (06/15)

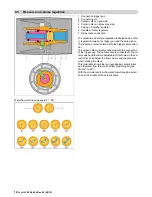

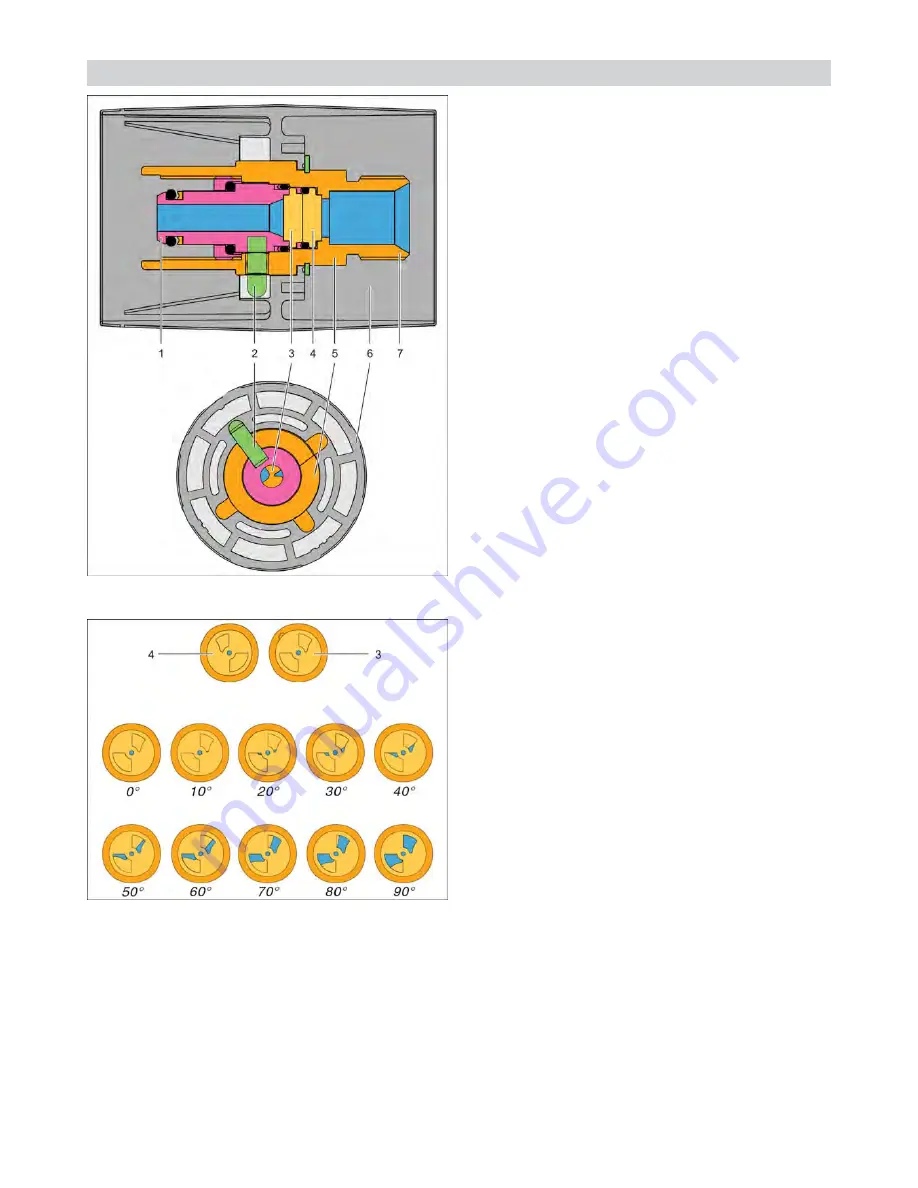

1 Connection trigger gun

2 Connecting pin

3 Ceramic disc on gun side

4 Ceramic disc on spray pipe side

5 Casing of rotating regulator

6 Handle of rotary regulator

7 Spray lance connection

The pressure and volume regulation is designed as a rota-

ry regulator between the trigger gun and the spray lance.

There are two ceramic discs within the high pressure chan-

nel.

The ceramic disc is rigidly connected with the connection

of the trigger gun. The ceramic disc is connected to the ro-

tary switch and therefore adjustable. Offset holes in the ce-

ramic discs can adjust the flow volume and the pressure

when rotating the discs.

This illustration shows the two overlapping ceramic discs

and the water flow (blue) with different opening angles

(from 0° to 90°).

With the minimal setting, the water flows through a small

hose in the middle of the ceramic discs.

Water flow with opening angle 0° - 90°

6.5

Pressure and volume regulation