【

9

】

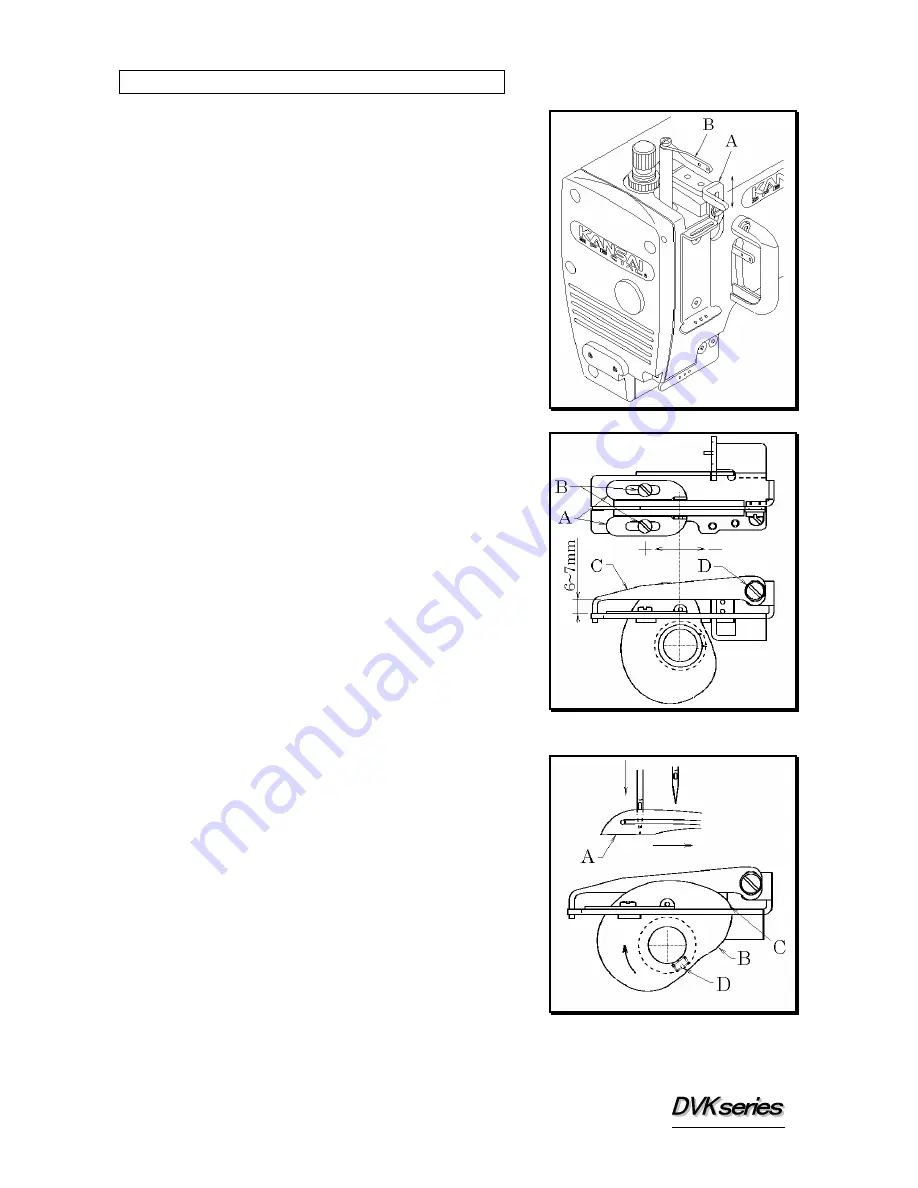

ADJUSTING THE STITCH FORMATION

9-1 Position of the thread support

When the needle bar is at the bottom of its stroke,

the centers of the eyes on thread eyelet A should be

level with the top surface of thread support B, and

A should be parallel with B.

Height adjustment of thread support B is made by

loosening screw C and moving thread support B up

or down. Moving thread support B up tightens the

needle thread. Moving thread support B down

loosens the needle thread.

9-2 Position of the looper thread eyelets

Align the eyes on looper thread eyelets A with the

center of the shaft. Adjust the position of the eyes

on looper thread eyelets A by loosening screws B

according to the sewing conditions such as the

fabric and/or thread to be used.

To increase the amount of the looper thread to be

supplied, move looper thread eyelets A toward the

rear side of the machine.

To decrease the amount of the looper thread to be

supplied, move looper thread eyelets A toward the

front side of the machine.

Thread guide C should be 6~7mm above the top

surface of the guide plate.

Adjustment is made by loosening screw D.

9-3 Position of the looper thread take-up

When the point of the needle has reached bottom

surface A of the looper blade while the looper is

moving to the right from the extreme left end of its

travel, the looper thread should be removed from

point C on looper thread take-up B.

Adjustment is made by loosening and then

tightening screw D.

10