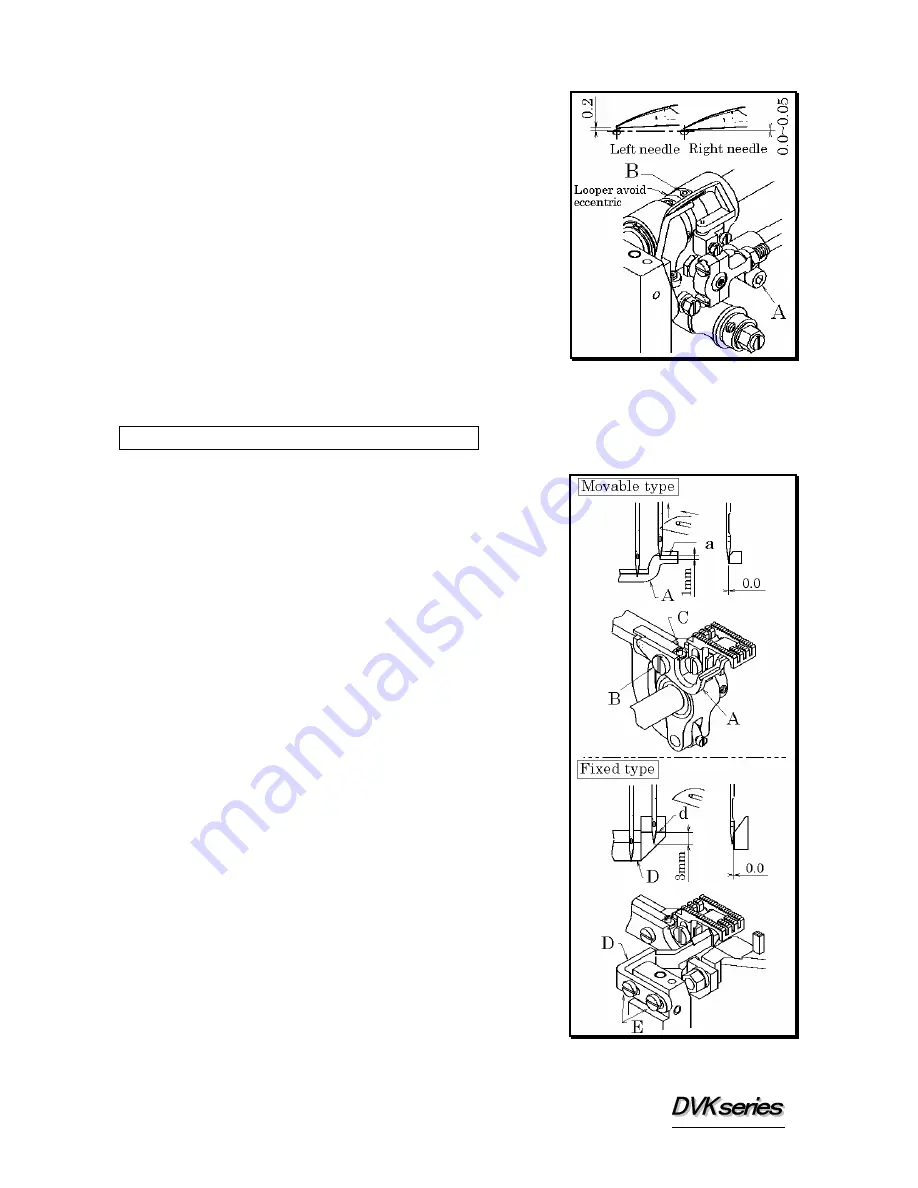

5-5 Needle/looper front-to-back relationship

When the looper passes on the back side of the needle,

the clearance between the right needle and the looper

should be 0~0.05mm. Adjustment is made by

loosening screw A. The clearance between the left

needle and the looper should be 0.2mm.

Adjustment is made by loosening screw B on the looper

avoid eccentric. To increase the clearance, turn the

looper avoid eccentric toward the back side of the

machine. To decrease the clearance, turn the looper

avoid eccentric toward the front side of the machine.

【

6

】

ADJUSTING THE NEEDLE GUARDS

6-1 Position of the needle guard (rear)

■

Movable type (for models except BK

,

PBK)

When the point of the looper has reached the center of

the right needle, the distance from the point of the

right needle to line (a) on needle guard A should be

1mm (approximately 2mm on EHD).

Then the clearance between the needle and the needle

guard should be 0mm.

Adjustment is made by loosening screw B and turning

screw C to move the needle guard up or down and/or

front or back as required.

■

Fixed type (for BK

,

PBK)

When the needle bar is at the bottom of its stroke, the

distance from the point of the right needle to line (d)

on needle guard D should be approximately 3mm.

Then the clearance between the needle and the needle

guard should be 0mm.

Adjustment is made by loosening screws E.

7