- 12 -

5.1. Smoke discharge system

Requirements:

•

In order to ensure normal operation of the boiler, continuously permanent sufficient chimney draught has to

be ensured (

see Table 1

).

Smoke extraction fan (smoke exhauster) has to be installed in the smoke

discharge circuit

. In the case of restructuring or building new boiler house, in order to reduce harmful

environmental impact, it is recommended to install a multicyclone (

see fig. 5, A and C

).

•

Height of the chimney shall be selected by designer in accordance to environmental requirements of the

location.

•

Smoke and air ducts of the boiler houses have to be made of steel (round or rectangular) with thermal

insulation.

•

Flue pipe shall be installed with the inclination of no less than 10 per cent and the bends towards the

chimney of no more than 45

.

•

Flue pipe can be installed not only directly from the end, but also by turning the branch pipe to one or the

other side of the collector, counterchanging with sooth removal lids.

•

Smoke exhausters have to be installed for each

boiler separately, according to manufacturer’s

recommendations, taking into account the multicyclone, if installed. Frequency converters are recommended

to use for smoke exhauster efficiency control in order to ensure economic and reliable operation of the boiler.

One shared or several separate chimneys for each boiler can be installed in the boiler houses. If shared

chimney is installed, each boiler, on separate branches, shall have smoke exhauster

(see fig. 5, C

).

It is

prohibited to install one smoke exhauster for two or more boilers (see fig. 5, D

).

•

Multicyclone is used to separate ash and other solid volatiles from the exhaust gas smoke). Its type and

efficiency is selected according to volume of combustion products, boiler power, following the manufact

urer’s

recommendations. Multicyclones are installed behind the boiler and before the smoke exhauster (

see fig. 4,

A

).

It is prohibited to install multicyclone behind the smoke exhauster

(

see fig. 5, B

). When there are

several boilers, multicyclones are installed separately for each boiler (

see fig. 5, C

). Multicyclone installation

has to be carried out in accordance with the building standards valid in the country of boiler operation.

•

Fixed points of measurement of discharged smoke draught, temperature and eco parameters have to be

installed in the flue pipes.

•

Explosion isolation valves have to be installed in the smoke ducts where explosive gases can accumulate.

•

Holes for sooth removal with sealing doors have to be installed in the smoke ducts and chimney.

•

Drainage system for condensate collection and discharge has to be installed at the bottom of chimney.

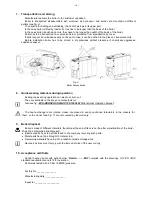

Fig. 5.

Model systems for smoke discharge to chimney:

1. Boiler. 2. Multicyclone. 3. Smoke exhauster. 4. Chimney. B and D are improper options.

As the boiler has high rates of efficiency, aerodynamic resistance gets larger and smoke temperature gets

lower, the chimney draught has to be higher than for the boilers with lower technical rate. Flue pipe and

chimney have to meet the following requirements (

see fig. 5

):

Содержание Kalvis-100MG

Страница 2: ......