10.6.5 Oil separator tank dirt trap maintenance

The control valve is mounted on the oil separator tank cover. The control valve has two different

dirt traps that must be cleaned at least once a year.

Material Cleaning cloths

Wrench

Small screwdriver

Maintenance kit, control valve

Petroleum ether or spirit

Precondition The machine is switched off.

The machine is fully vented, the pressure gauge reads 0 psig.

The machine has cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

The «battery isolating switch» is turned off.

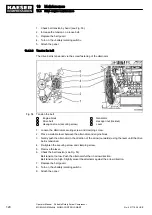

Fig. 61 Oil separator tank dirt trap maintenance

1

Oil separator tank cover

2

Control valve

3

Union nut

4

Oil return line

A

Detail: Dirt trap, oil return line

5

Strainer

6

Sealing ring

7

Screw-in connector

8

Nozzle

B

Detail: Dirt trap, proportional controller

9

Screw plug

10

O-ring

11

Strainer

➤ Remove the left-front panel.

10.6.5.1 Oil return line dirt trap maintenance

See Fig. 61; Detail: A.

1. Completely remove the union nut

3

and bend the oil return line

4

to one side.

2. Unscrew the screw-in connector

7

.

3. Unscrew the strainer

5

from the screw-in connector.

4. Use a screw driver to unscrew the nozzle

8

from the screw-in connector.

5. Clean the housing, strainer and sealing ring

6

with cleaning solvent or spirit.

6. Check the nozzle, strainer and sealing ring for wear.

When clearly worn: replace components.

10 Maintenance

10.6 Compressor Maintenance

No.: 901779 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M58utility SIGMA CONTROL SMART

137