PK3520_09_07 • REMOTE ACCESS CONTROLLER - 660G XT

13

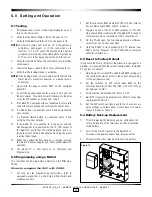

4. Remove nuts, split washers, and flat washers holding

down the battery brackets;

5. Rotate the battery brackets upward to remove it from the

anchoring slots as shown in figure 15.

6. Replace the used battery with the same type gelled lead

acid cell 12V, 7.0 Ah (Ampere-hour).

CAUTION: Dispose of used battery according to local

regulations

!

7. Place new battery in the battery location, as shown in figure 15,

ensuring that the orientation is as, the "+" terminal shown being

the lowest.

8. Install the battery brackets, flat washer, split washers, nuts in this

order and reconnect the wires from the power supply (B) to the

battery (K) ensuring that the red wire connects to the '+' terminal

and the black wire connects to the '-' terminal.

9. Reconnect the power adaptor or turn on the main AC power to

the 660G XT.

NOTE:

For preventive maintenance, the battery back-up should be

replaced every 2 to 3 years, and tested every 6 months by

removing the main AC power.

5.5 New Battery Back-up Installation

Post-installation of the system, if it is decided that the system should

have a battery back-up, order kit 064-511889-K and follow the steps

below.

1. Turn off the main AC power to the 660G XT or disconnect the

power adaptor.

2. Connect the end with the fork crimp terminal of the red wire

supplied with the battery back-up kit to the ‘+’ terminal on the

power supply terminal block BAT. Ensure that the power supply

screw is appropriately tightened to secure the wire.

3. Connect the end with the fork crimp terminal of the black wire

supplied with the battery back-up kit to the ‘-‘ terminal on the

power supply terminal block BAT. Ensure that the power supply

screw is appropriately tightened to secure the wire.

4. Place the battery back-up in the battery location as shown

in figure 15, ensuring that the orientation is as shown, the

positive terminal being the lowest.

5. Attach the battery brackets as indicated in figure 15 by hooking

one end of the brackets under the anchoring slots on the side

of the enclosure and the other end over the threaded posts.

6. Install, in sequence, the flat washers, split washers, and nuts,

tightening as needed.

7. Connect the wires from the power supply (B) to the battery (K)

ensuring that the red wire connects to the ‘+’ terminal and the

black wire connects to the ‘-‘ terminal.

8. Reconnect the power adaptor or turn on the main AC power to

the 660G XT.

NOTE:

For preventative maintenance, the battery back-up should be

replaced every 2 to 3 years, and tested every 6 months by

removing the main AC power.

5.6 Power Failure

In the event of an electrical failure, the system will revert to battery

back-up status for a period of 4 hours. If the electrical power is

restored within 3 days the system will recover automatically and

should require no additional programming.

When electrical power is restored after a power failure verify the

status of the LED D41 on the controller board (C). Refer to Annex

A, Table 3 for Status LED definitions. If the LED is OFF reprogram

controller board (C).

NOTE:

When the voltage of the battery back-up is too low the

controller board stops working and the relay on the controller

board (C) will return to its normal state. The peripheral

connected to the relay will then be either in a normally open

(NO) or normally closed (NC) state dependent on the wiring of

the device to the controller board (C).

5.7 Loading Recommendations

CAUTION: Do not exceed the load limitations

of the control panel.

!

The maximum recommended load for all output relays in the card

reader control panel is 1 Amp at 30 VDC. The tamper switch rating

is 1 Amp at 30 VDC.

The current supplied by the controller board (C) for the locking device

used is 0.75 Amps from connector J18, pin 1. Refer to Annex A,

Table 1.

5.8 System Deactivation

In order to deactivate the card reader control panel, disconnect both

terminals from the battery back-up, then disconnect the AC power

either by removing the power adaptor from the wall outlet, or by

shutting off the main breaker switch for the AC line to the wall outlet

the control panel is connected to.