Содержание KS-72

Страница 12: ...11...

Страница 13: ...12...

Страница 22: ...21...

Страница 23: ...22...

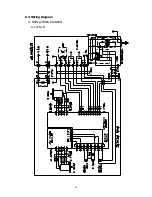

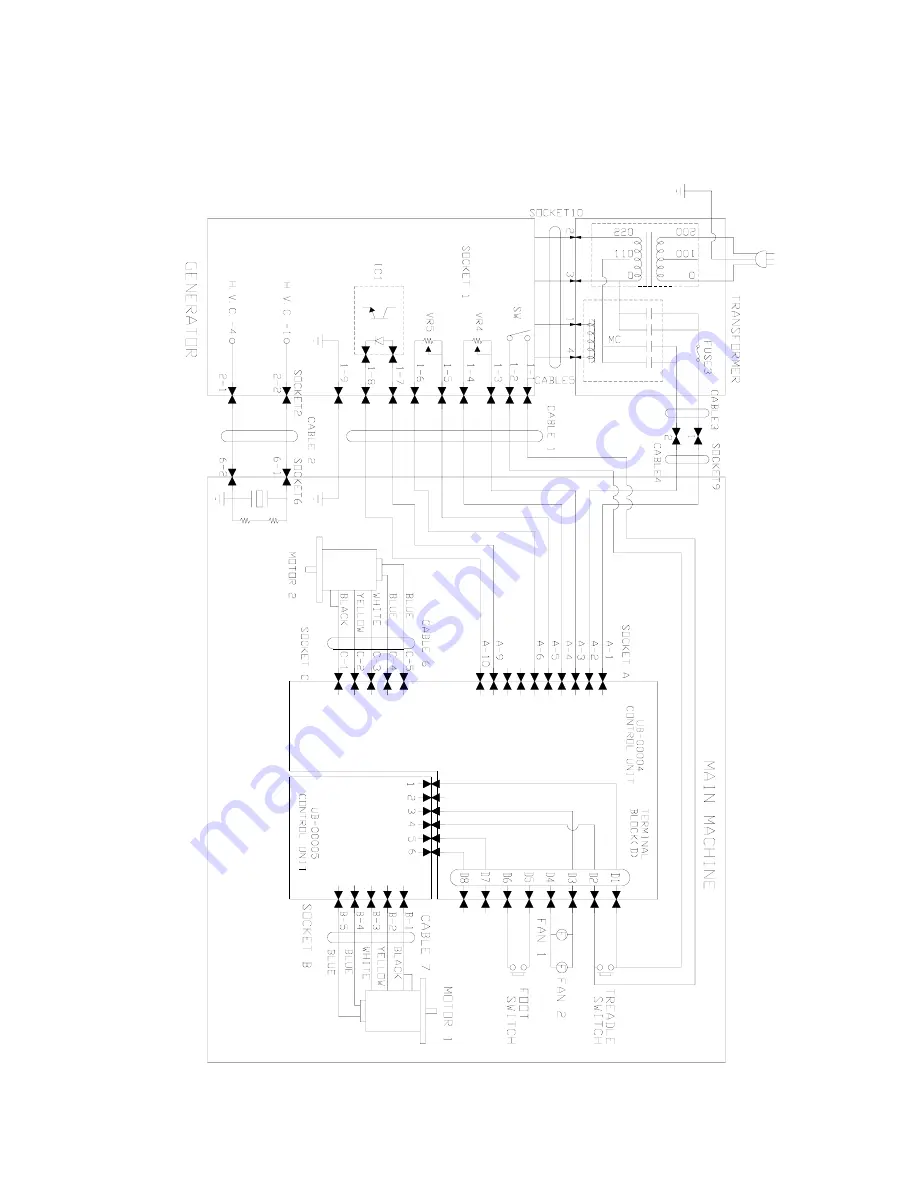

Страница 31: ...30 6 4 Wiring Diagram A MAIN WIRING DIAGRAM A 1 KS 72...

Страница 32: ...31 A 2 KS 85...

Страница 35: ...34 1 2W 10W 1 2W 6 5 Circuit Diagram A MOTOR SPEED CONTROL CIRCUIT DIAGRAM A 1 KS 72 UPPER MOTOR WORKING ROLLER...

Страница 38: ...37 FUSE FUSE B GENERATOR CIRCUIT DIAGRAM KS 72 KS 85 KS 2010 KS 3010...