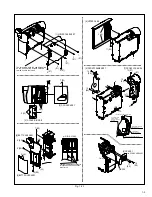

1-4

F3

E3

D2

C3

A2

A SIDE VIEW

SOLDER ALL SURROUNDINGS

A

OF TERMINALS

NOTE THE UNDERMENTIONED CONYENT WHEN SOLDERING.

B2

[10] MAIN BOARD ASSY

18

(S10)

19

(S10)

2 (SD10)

CN3

CN7

CN2

CN5

CN1

CN4

D2

C2

E1

b

F1

F2

e

d

E2

D1

c

C1

A1

B1

a

C3

F3

F2

E2

E3

C2

A2

B2

[11] SHIELD PLATE

20

(S11)

21

(S11)

22

(S12)

23

(S12)

FRAME ASSY

b

d

E1

F1

e

C1

c

D1

B1

A1

a

[12] MECHANISM ASSY

24

(S12)

ATTACH TERMINALS.

FRAME

TERMINAL 3

TERMINAL 2

INSERT TERMINAL 1 IN

THE INTERIOR , SURELY .

A

IT HANGS IT

IT PUTS THE

POINT IN THE

HOLE .

TERMINAL 2 AND TERMINAL 3 HANG

ON THE HANGING PART , AND PUT

THE TERMINAL POINT AT THE END .

IT HANGS IT

TERMINALS ARE INSTALLED IN THE

POSITION OF FIGURE .

A SIDE VIEW

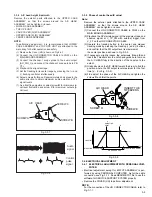

FRONT COVER SA

a

b

c

a

c

b

PART A OF MIC (CUSHION)

IS DRAWN OUT FROM THE HOLE .

DITCH PART B IS MADE TO

ENTER AROUND ALL THESE PARTS .

MIC (CUSHION) .

INTERIOR OF MIC (CUSHION) ,

AND MIC IS COVERED WITH

MIC IS INSERTED IN THE

AND PART c .

THE RIB OF MIC CAP IS PUT

OUT FROM PART a , PART b ,

THE RABBER FRAME OF CUSHION .

MIC CAP IS COVERED WITH

THE CONNECTOR OF MIC IS PUT OUT

FROM THE INSIDE OF CUSHION

OUT SIDE THROUGH THIS SLIT PART .

CONNECTION PART OF WIRE

IS MADE TO COME NEAR IS

THIS DITCH .

WHILE DRAWING OUT MIC WIRE

COVER MIC CAP WITH CUSHION

FROM CUSHION .

FRONT COVER ASSY

MIC CAP

CUSHION

MIC ASSY

CUSHION(ECM)

TAP SCREW x3

MIC ASSY

CUSHION(ECM)

CUSHION

MIC CAP

MIC CAP

Fig. 1-2-2