2-10

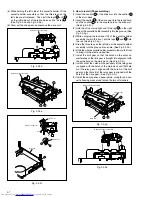

Fig. 2-2-11a

2. How to install

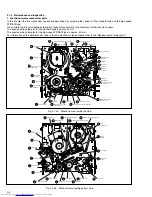

(1) Install the clutch gear, spring (A), spring (C), direct gear,

spacer and others to the individual shafts of the main

deck, and finally the slit washer. (See Fig.2-2-12a.)

(2) Let the spring (B) drops into the rotary encoder guide hole

and install the change lever assembly.(Take care not to

mistake a direction of the spring.) The point is to slightly

lift the clutch gear and catch it from the both sides with

the assembly. (See Fig.2-2-12b.)

Slit washer

Belt

Clutch unit

2.2.11 Clutch Unit

(1) Remove the belt wound around the capstan motor and

the clutch unit.

(2) Remove the slit washer and remove the clutch unit.

Fig. 2-2-12b

Fig. 2-2-12a

Spacer

Change lever

assembly

Direct gear

Clutch gear

Spring (C)

Slit washer

Lugs

Spring(A)

Position the projecting

side down.

Spring(B)

Washer (

*

1)

Spacer (

*

1)

Coupling gear (

*

2)

Spring(B)

Rotary encoder guide

Main deck

Main deck

Change lever assembly

Clutch gear

2.2.12

Change Lever Assembly, Direct Gear, Clutch

Gear and Coupling Gear

1. How to remove

(1) Release the two lugs of the rotary encoder guide in the

arrow-indicated direction and remove the change lever

assembly.

(2) Remove the slit washer retaining the direct gear and re-

move the latter.

Take care so as not to lose the washer and spring. (See

Fig.2-2-12a.)

2.2.10 Rotary Encoder

1. How to remove

(1) Remove the screw (A) and remove the rotary encoder

by pulling it up. (See Fig. 2-2-10a.)

Fig. 2-2-10a

Rotary encoder (Front side)

Screw(A)

Rotary encoder (Back side)

Positioning pin of the rotary encoder

Guide marks

Fig. 2-2-10b

2. How to install (Phase matching)

(1) Make sure that the mark E of the control plate is in align-

ment with the mark of the loading arm gear shaft and

bring the guide marks on the rotary encoder into align-

ment as indicated in Fig.2-2-10a. (See Fig. 2-2-10a and

Fig. 2-2-10b.)

(2) Turn over the rotary encoder with its guide marks kept in

alignment and install it by fitting on the shaft of the rotary

encoder guide and the positioning pin.

(3) Tighten the screw (A) to complete the installation.

Control plate

Shaft of the rotary encoder guide

Mark E

Note:

• The parts with marked (

*

) have different types of mechanisms (standard type or high-

speed FF/REW type).

*

1 : Uses the standard type mechanism only.

*

2 : Uses the high-speed FF/REW type mechanism only.