2-6

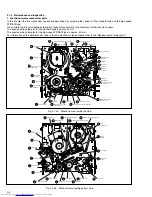

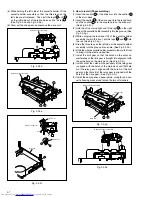

(4) While swinging the lock levers (R) and (L) of the cassette

holder assembly toward the front, slide the cassette

holder assembly until its legs come to where the guide

rail and the roller cam assembly have been removed (so

that the drive arm is upright). (See Fig.2-2-3c.)

Fig. 2-2-3c

Cassette holder assembly

Lock lever (L)

Drive arm

(Upright)

Leg

Legs

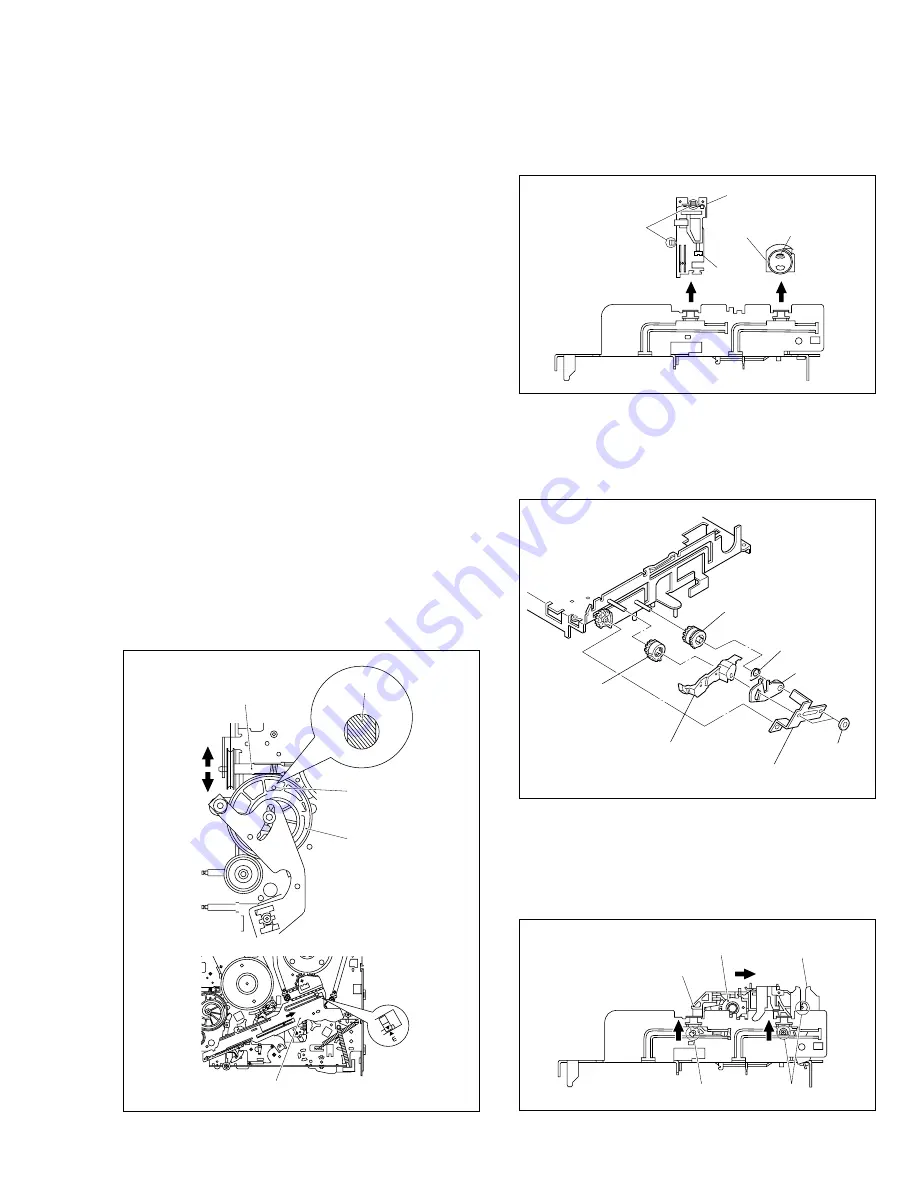

2.2.3

Cassette Holder Assembly

1. How to remove

(1) Remove the guide rail and roller cam assembly. (See

Fig.2-2-3a.)

(3 lugs on the guide rail and one lug on the roller cam

assembly)

Fig. 2-2-2a

Worm gear

Guide hole

Control cam

Chassis hole

Control plate

Mark E

Fig. 2-2-3b

(2) Remove the two slit washers and remove the cassette

housing bracket. (See Fig.2-2-3b.)

(3) Remove the opener guide, spring(A), door opener, relay

gear and limit gear. (See Fig.2-2-3b.)

Fig. 2-2-3a

Lugs

Lug

Lug

Guide rail

Roller cam

assembly

Limit gear

Relay gear

Opener guide

Spring(A)

Cassette housing bracket

Slit washers

Door opener

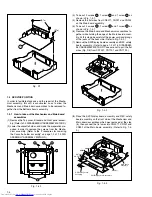

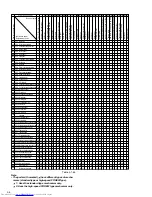

2.2 REPLACEMENT OF MAJOR PARTS

2.2.1

Before Starting Disassembling (Phase matching

between mechanical parts)

The mechanism of this unit is closely linked with the rotary

encoder and system controller circuits.

Since the system controller detects the status of mechani-

cal operation in response to phases of the rotary encoder

(internal switch positions), the mechanism may not operate

properly unless such parts as the rotary encoder, control

plate, loading arm gear, control cam, cassette gear, limit gear,

relay gear and drive gear are installed in their correct posi-

tions.

Especially, this model is not provided with any cassette hous-

ing assembly, so that cassette loading and unloading must

be accomplished by operation of the cassette holder assem-

bly. The latter is in turn driven by such parts as the drive

gear, relay gear and limit gear. Exercise enough care, there-

fore, to have the phases of all this gear matching one an-

other. (For information on phase matching of the mechanism,

see the instructions on how to install individual parts.)

This unit is provided with a mechanism assembly mode. It is

therefore necessary to enter this mode for assembling and

disassembling procedures.

This mode is usually not in use, manually set it when it is

required.

2.2.2

How to Set the Mechanism Assembling Mode

Remove the mechanism assembly and place it bottom side

up. (See SECTION 1 DISASSEMBLY.) Turn the worm gear

toward the front so that the guide hole of the control cam is

brought into alignment with the hole at the mechanism as-

sembly chassis. This position renders the mechanism assem-

bling mode operational. Make sure that the control plate is

located in alignment with the mark E. (See Fig.2-2-2a.)