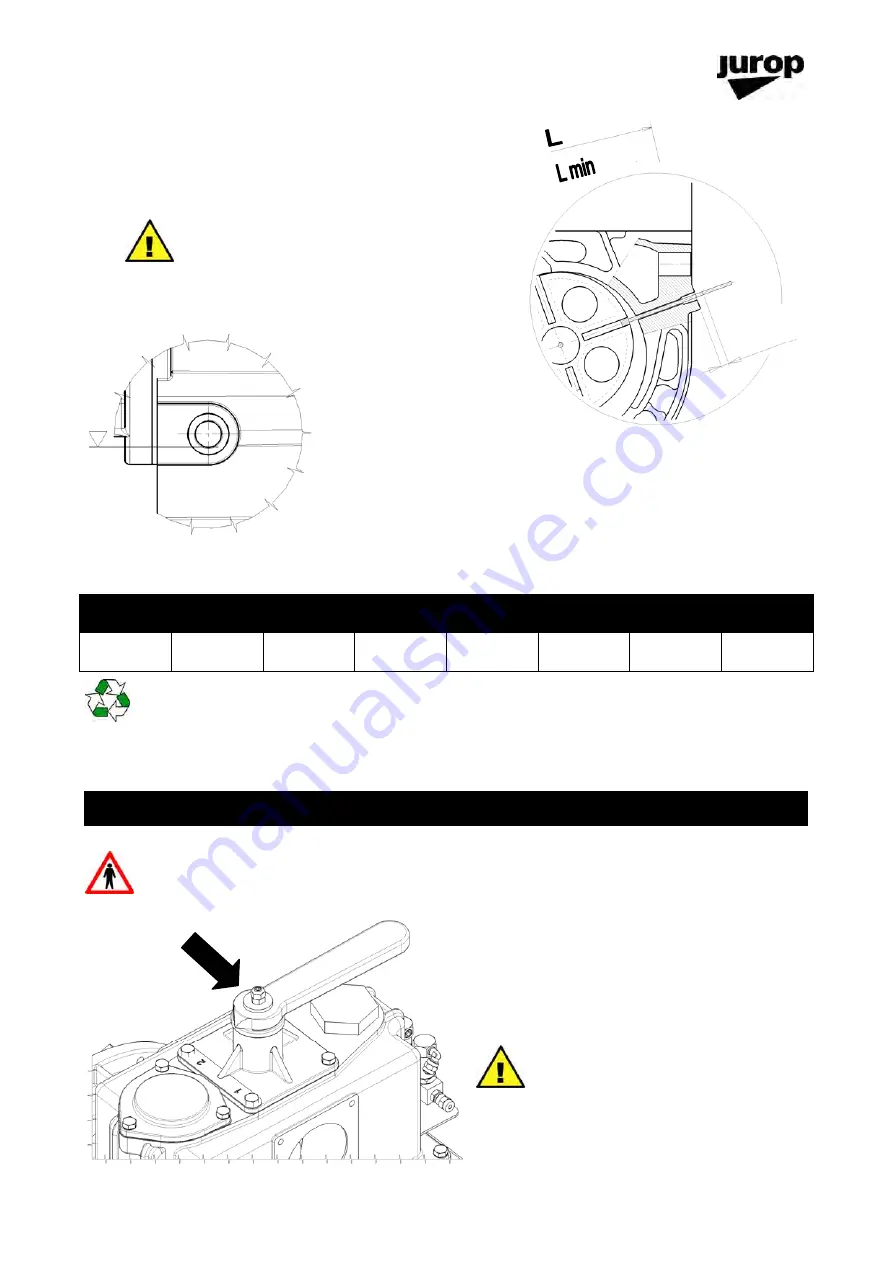

CHECKING THE VANES WEAR

•

Unscrew the vanes wear check-plug on the housing.

•

Turn the shaft until you see the vane.

•

The vanes should slide to the bottom of the seat due to

gravity: check they really do.

Replace the vanes when their wear exceeds 10

mm (L – L min): they may break. Replace all

vanes at the same time.

CHECKING THE GEAR BOX OIL LEVEL

Check the level when the pump is cooled: it must almost reach

the threaded port. Refill if necessary.

For a complete replacement, 0.7 litres are required. Use mineral

oil with EP additives for gears and transmissions.

Recommended lubricants

Viscosity

Type

AGIP

ESSO

SHELL

ELF

MOBIL

BP

ISO

VG 220

EP mineral oil

BLASIA

220

SPARTAN EP

220

OMALA OIL

220

REDUCTELF

SP 220

MOBILGEAR

630

ENERGOL GR

XP 220

Dispose of exhausted oil as provided by current specification.

When changing the oil, also replace the outlet plug washer.

Before starting any extraordinary maintenance operation, be sure the pump stands still and

follow the safety prescriptions as described in paragraph “Safety and accidents prevention”.

ADJUSTING THE 4-WAY VALVE

For pumps equipped with handle for manual

operation or hydraulic actuator.

Adjust the screws to avoid the valve blocking

in its seat.

Do not exceed with the adjustment:

possible vacuum loss.

For pumps equipped with changeover valve

with hydraulic actuator: see the integrated

part at the end of these instructions.

12. EXTRAORDINARY MAINTENANCE

www.fraserwoods.ca