Before starting any maintenance operation, follow the safety prescriptions as described in

paragraph “Safety and accidents prevention”.

PUMP OPERATION

CONDITION

CHECKING

FREQUENCY

OPERATING

Lubrication: dripping into oilers

D

Rotating speed

D

Working pressure

D

STANDSTILL

Side mounted tank oil level

D

Clean filter and vacuum line shutoff.

Drain the oil gathered in the exhaust separator.

D

Check vanes wear

W

Check pressure relief valve condition

M

Gear box oil level

M

Gear box oil change

1500 h

Frequency:

D

: daily

W

: weekly

M

: monthly

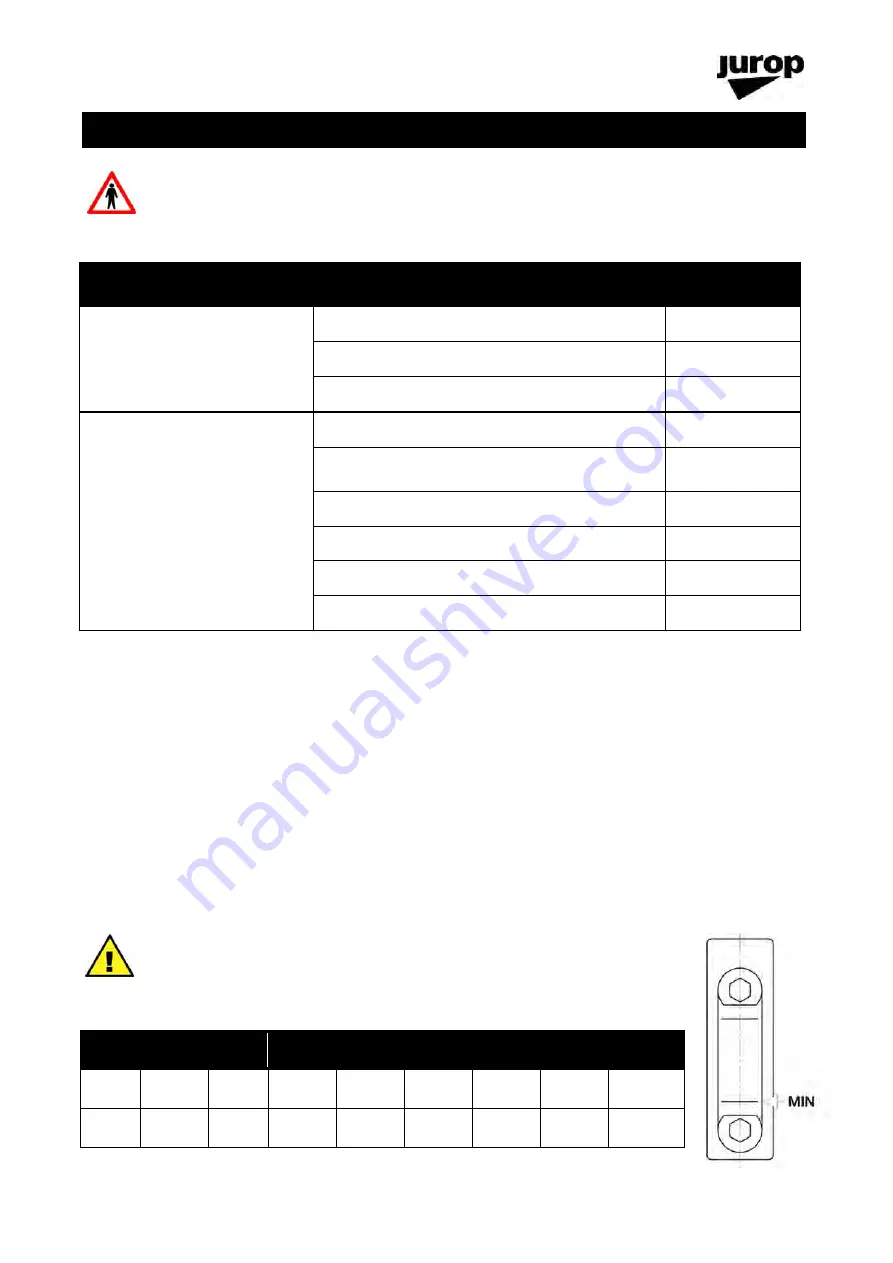

CHECKING THE DRIP OILERS

Check dripping into the oilers.

Be sure it is regular (app. 35 drops/min at max. speed) to grant a correct lubrication of the pump. At

lower speeds, the number of drops must be directly proportional.

CHECKING THE SIDE MOUNTED OIL TANK LEVEL

Do not run the pump with oil level under the minimum level: that may lead to dry functioning and cause

serious damages. Tank capacity: 4 litres. Use pure fresh oil.

Do not re-use the exhausted oil gathered on the bottom of the exhaust silencer.

Recommended lubricants

Room.

Temp.

Viscosity

Type

AGIP

ESSO

SHELL

ELF

MOBIL

BP

Below

10°C

ISO

VG 46

Mineral

oil

RADULA

46

NURAY

46

VITREA

46

MOVIXA

46

RUBREX

300

ENERGOL

CS 46

Above

10°C

ISO

VG 150

Mineral

oil

RADULA

150

NURAY

150

VITREA

150

MOVIXA

150

RUBREX

900

ENERGOL

CS 150

11. ORDINARY MAINTENANCE

www.fraserwoods.ca