– 7 –

1. After the adjustment, idle the sewing machine at the sewing speed to be used for sewing about

30 seconds. Then, check the oil quantity by comparing with the sample which shows the appro-

priate oil splash (marks).

2. When adjusting the amount of oil in the hook, perform the adjustment in a way of reducing the

oil amount after somewhat increasing it.

3. The amount of oil in the hook has been adjusted at the max. sewing speed at the time of delivery.

When you always use the sewing machine at low sewing speed, there is a possibility that trouble

occurs due to the lack of amount of oil in the hook. When the sewing machine is used always at

low sewing speed, perform the adjustment of the amount of oil in the hook.

4. There is a possibility of causing oil leakage from the hook shaft section since oil does not return

to the oil tank when oil amount adjustment screw

❶

is used in fully-tightened state. Do not use

the screw in fully-tightened state. In addition, when the amount of oil in the hook is not obtained

unless oil amount adjustment screw

❶

is near in fully-tightened state, it is considered that hook

shaft oil wick (JUKI Part No. 11015906) is clogged or the like. Replace the hook shaft oil wick.

5. Never adjust screw

❷

of the hook oil quantity adjusting valve since it is fixed.

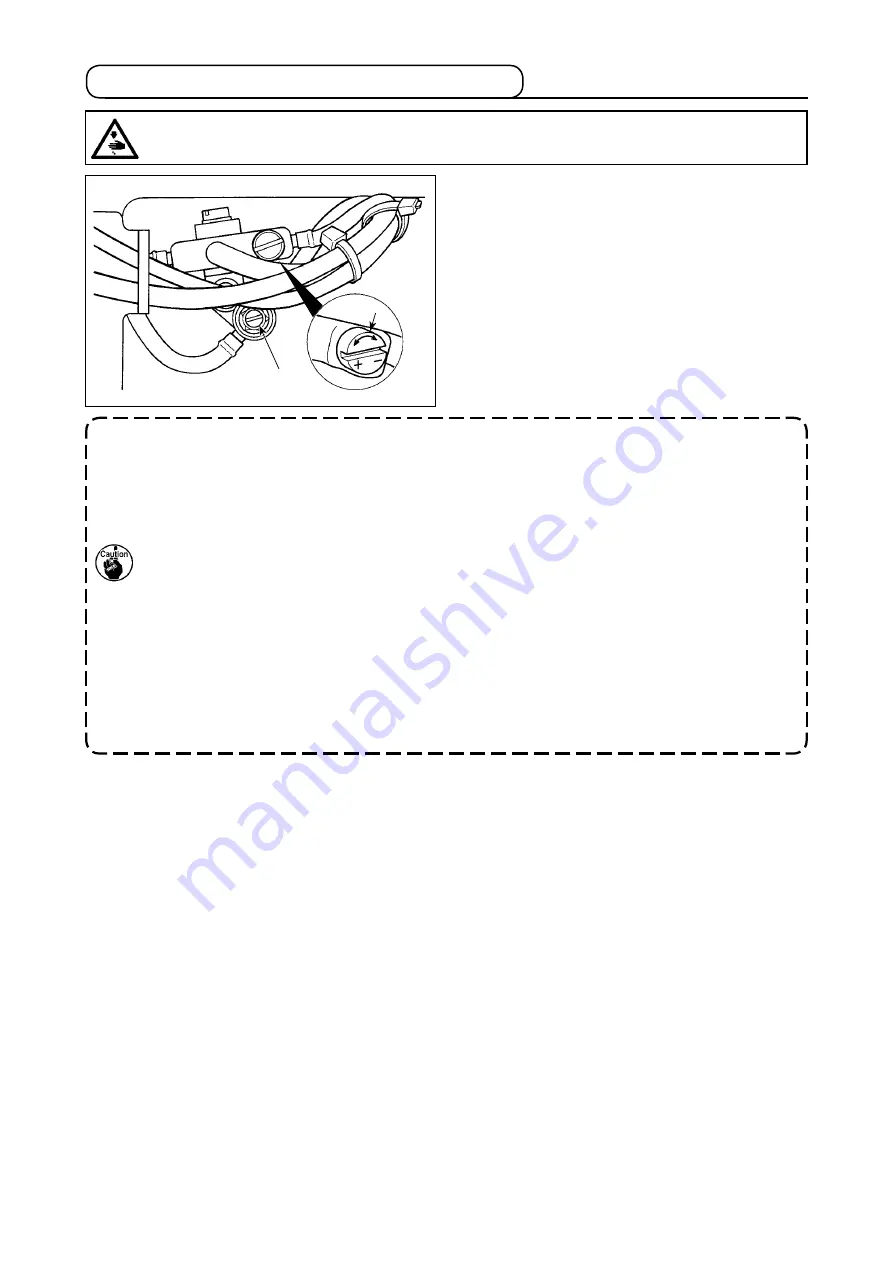

Tilt the machine head, and adjust the amount of oil in

the hook by turning the oil amount adjustment screw

❶

mounted on the gear box B.

Turn the adjusting screw in the “+” direction (counter-

clockwise) to increase the amount of oil in the hook.

Turn the adjusting screw in the “–” direction (clockwise)

to decrease it.

3-2. Adjusting the amount of oil in the hook

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

❷

Содержание LZ-2280A Series

Страница 1: ...LZ 2280A Series INSTRUCTION MANUAL ...