Operation manual

Ⅰ

3

−

2

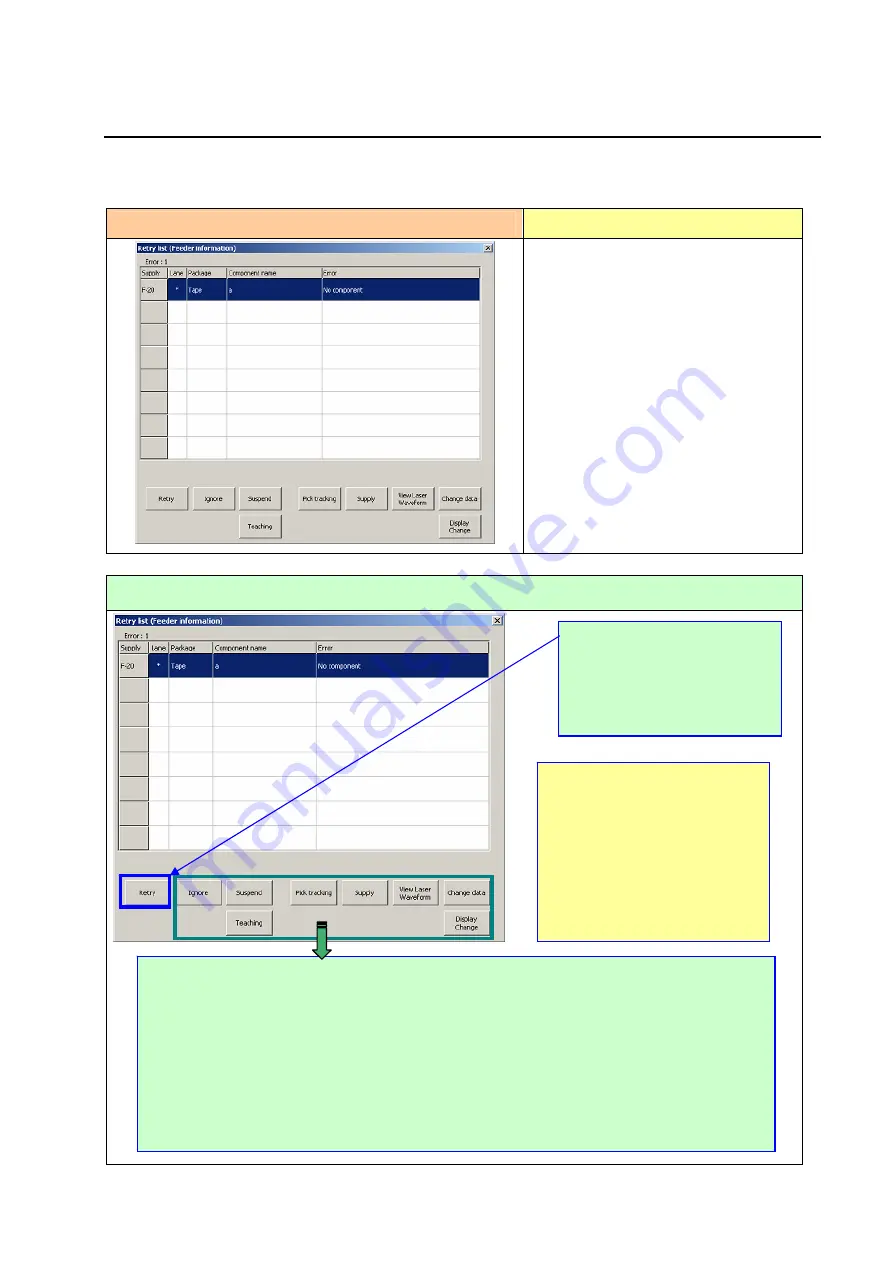

3.2 When components run out

(If the check box “Stop system when

components run out” is not checked on the “Operation option” screen)

After the machine finishes placing all components that can be placed on boards, the

following screen appears and the mounter stops temporarily.

Error screen

Causes of the error

①

The stocked components run out.

②

The machine failed to pick up a

component.

(Due to jammed peel-off tape or a

pick-up position error caused by

defective tape feeding)

How to handle an error

☆

Ignore:

Skips a component that caused a component run-out error to produce the next PWB.

☆

Suspend:

Suspends the current PWB production.

☆

Pick tracking:

Uses a camera to execute the component pick-up position correction process.

☆

Supply:

Allows you to set the number of components.

☆

View Laser Waveform:

Displays the laser waveform. See Section 3.4 “When a laser sensor is

stained” for details.

☆

Display change:

Switches the screens between the “Not placed” list and the “Feeder

Information.”

☆

Change data:

Allows you to change the Component data.

☆

Teaching

: Pick position tracking can be performed.

After replenishing the machine

with components or removing the

cause of a component run-out

error (such as jamming of tape),

select the <Retry> button, and

then press the <START> switch.

*When you press the <CAMERA>

button of the HOD while the

machine stops because

components run out, you can

recheck the pick-up position where

a component run-out error

occurred again. If a component

pick-up error is substantial,

perform a teaching operation.