Operation manual

Ⅰ

2

−

1

Chapter 2

Operation Procedure

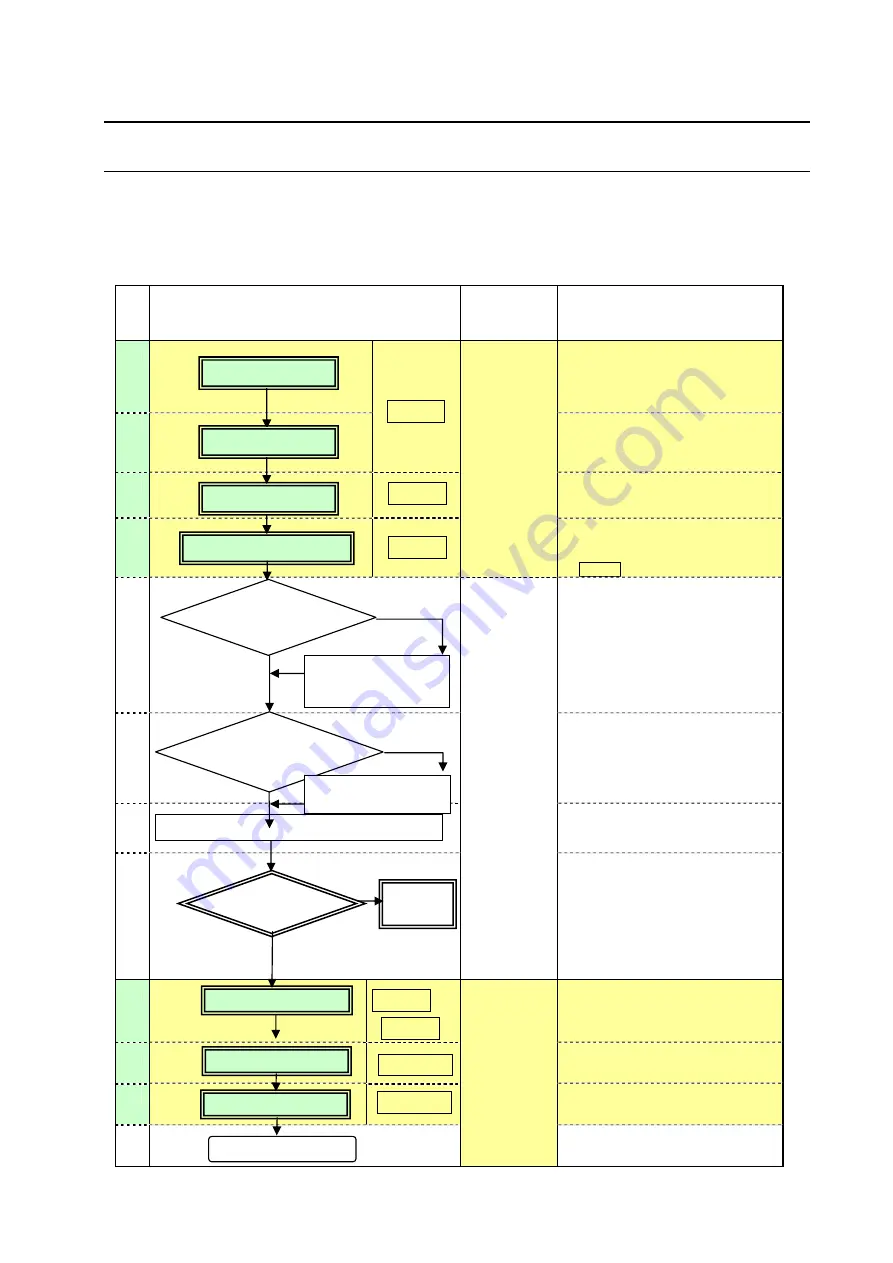

2.1 Flow of PWB production

The following flow chart indicates the operation flow from power-on to the end of PWB

production.

To perform a routine PWB production, follow the operations in order: No. 1, No.2, No.

3, No. 4, No. 9, No. 10, and No. 11.

No Flow

chart

Person who

operates the

machine

Comment

1

Perform this operation only after you

perform inspections such as checking

of the main air pressure (0.5 Mpa) and

checking to see if there is no foreign

substance around the ATC.

2

Check to see if there is no foreign

substance inside the machine before

production.

3

Be sure to warm up the system after

holidays or in cold climates (it takes

approximately 10 minutes).

4

Operator

When you change a PWB type to be

produced, you have to adjust the

conveyor to the size of the PWB. Refer

to

STEP 5

.

5

When the initial setup conditions of the

machine change due to cleaning of the

nozzle or change of the reference pin

position, set the “Machine setup” items

again. (Refer to Section 4.4 “Machine

setup” of the “Operation Manual II.”)

6

Refer to the “Operation Manual II.”

7

8

Programmer

Administrator

If any problem occurs during PWB

placement:

for example, the PWB position is shifted

from the regulated position or the

centering function fails, correct the

production program on the “Program

Editor” menu. You can correct a part of

component data on the “Production”

menu also.

9

10

11

12

Operator

Refer to Chapter 5 “Daily maintenance”

of the “Operation Manual II.”

PWB placement

confirmation

No problem

Correct the

program.

Problem

Yes

Creation/Ed

i

tion of your production program

Change the machine

setup conditions?

No

Create the component

database?

Yes

No

Change the desired

settings on the Machine

setup menu.

Create component data

on the “Database” menu.

Open the production file

.

Power ON

Warm-up

Origin return

STEP1

STEP2

STEP3

Production

Power OFF

Daily inspection

End of production

STEP4

~

STEP9

STEP10

STEP11