– 2 –

22. Motor PuLLEYs anD BELts

1) A clutch motor with 400W output (1/2 HP) is used as the standard motor.

2) An M-type V belt should be used.

3) The relatonshp between the motor pulleys, belt lengths and sewng speeds s shown n the followng

table :

* the effective diameter of a motor pulley is equivalent to the outside diameter minus 5 mm.

* the motor should rotate counterclockwise as observed from the handwheel side. Be careful

not to allow the motor to rotate in the reverse direction.

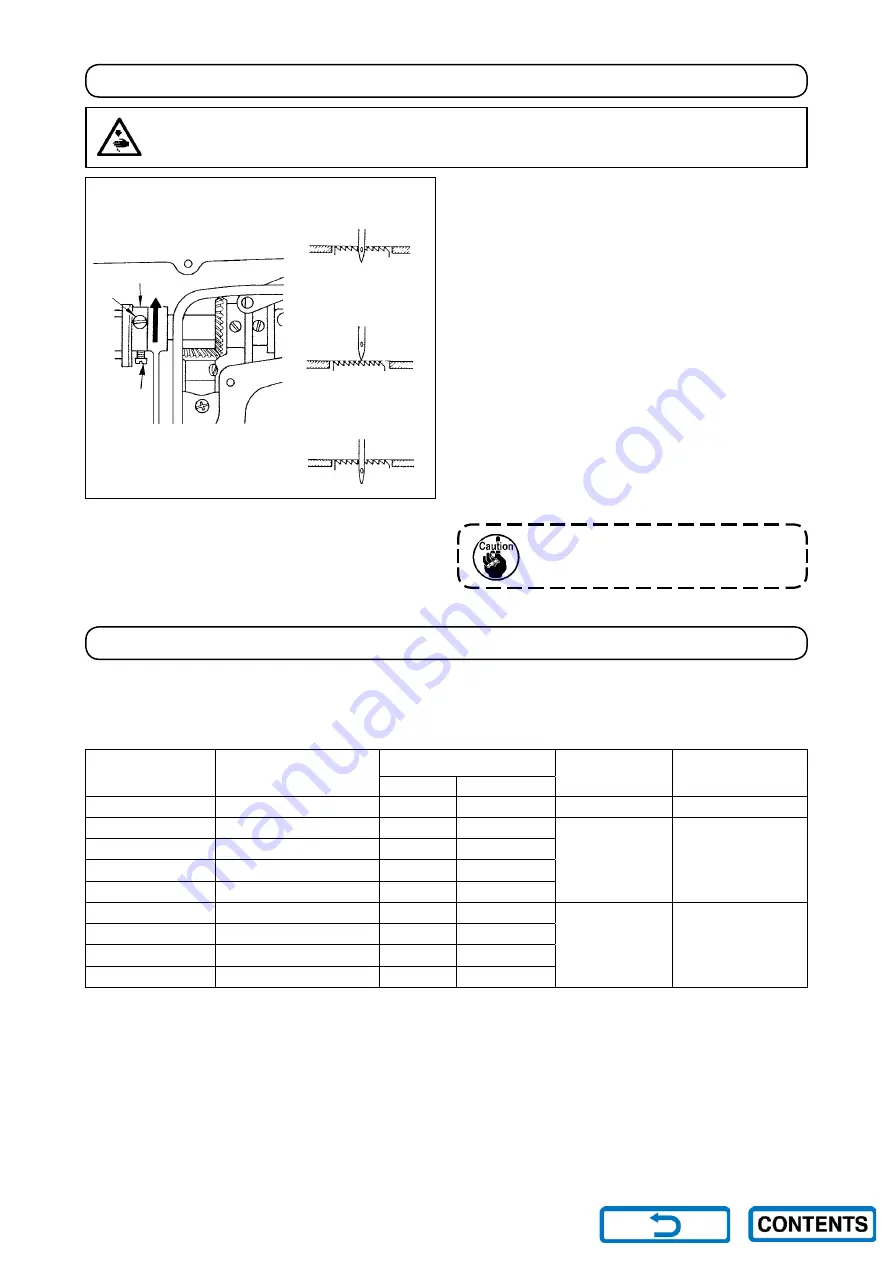

) Loosen screws

2

and

3

n feed eccentrc cam

1

,

move the feed eccentrc cam n the drecton of

the arrow or opposte drecton of the arrow, and

firmly tighten the screws.

2) For the standard adjustment, adjust so that the

top surface of feed dog and the top end of needle

eyelet are flush wth the top surface of throat

plate when the feed dog descends below the

throat plate.

3) To advance the feed tmng n order to prevent

uneven materal feed, move the feed eccentrc

cam n the drecton of the arrow.

4) To delay the feed timing in order to increase stitch

tghtness, move the feed eccentrc cam n the op

-

poste drecton from the arrow.

Be careful not to move the feed eccen-

tric cam too far,or else needle break-

age may result.

21. aDJustInG tHE FEED tIMInG

WarnInG :

to avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

standard feed timing

advanced feed

timing

Delayed feed timing

1

3

2

Motor pulley

o.D. (mm)

Motor pulley part no.

sewing speed (sti/min)

Belt length

Belt part no.

50 Hz

60 Hz

110

MTKP0105000

4,440

-

1092 mm (43")

MTJVM004300

105

MTKP0100000

4,250

-

1067 mm (42")

MTJVM004200

100

MTKP0095000

4,000

-

95

MTKP0090000

3,820

-

90

MTKP0085000

3,610

4,320

85

MTKP0080000

3,390

4,000

1041 mm (41")

MTJVM004100

80

MTKP0075000

3,160

3,790

75

MTKP0070000

2,950

3,520

70

MTKP0065000

2,740

3,260