– 111 –

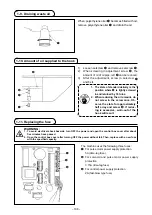

(1) Points to be applied with JUKI Grease A

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start

or the sewing machine. In addition, attach the covers which have been removed before operation

back in place.

Use grease tube A (part number: 40006323) (in light blue) supplied with the unit for add-

ing grease to any points other than the points specified below. If any grease other than

the specified one is used, the related components can be damaged.

❷

❻

❻

❷

❼

❶

❽

❾

❺

❹

■

Adding grease to the needle bar upper and lower bushings section, slide block section and

intermediate presser bar lower bushing section

1) Open the frame cover to remove intermediate

presser auxiliary spring B

❶

.

2) Apply JUKI Grease A onto periphery of needle

bar

❷

. Turn the sewing machine by hand to

apply grease onto the entire periphery of the

needle bar.

Turn needle bar upper bushing grease cover

❸

in the direction of arrow A to add grease

through the grease inlet. After completion

of the procedure, turn the needle bar upper

bushing grease cover in the direction of arrow

B to return to its home position.

Remove setscrew

❹

from the needle bar

lower bushing grease hole. Put JUKI Grease

A through hole

❺

and tighten setscrew

❹

to

fill inside the busing with the grease.

3) Apply JUKI Grease A also onto groove section

❻

of the slide block.

4) Apply JUKI Grease A onto periphery of inter-

mediate presser bar

❼

.

Remove setscrew

❽

from the intermediate

presser bar bushing grease hole. Put JUKI

Grease A through inlet

❾

. Tighten screw

❽

to fill inside the bushing with JUKI Grease A.