– 103 –

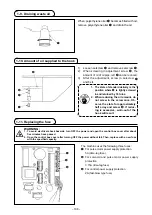

1-1. Adjusting the height of the needle bar (Changing the length of the needle)

* Turn ON the power once, and turn OFF the power again after making the intermediate press-

er in the lowered state.

1) Bring needle bar

❶

down to the lowest position of its stroke. Loosen needle bar connection screw

❷

and adjust so that the upper marker line

❸

engraved on the needle bar aligns with the bottom end of

the needle bar bushing lower

❹

.

2) As illustrated in the above figure, change the adjusting position in accordance with the needle count.

After the adjustment, turn the pulley to check for an extra load.

1. MAINTENANCE

❺

: Market line for DP x 17

(with needle count higher than #22)

❻

: Marker line for DP x 17

(with needle count lower than #22)

1-2. Adjusting the needle-to-shuttle relation

❺

: Marker line for DP x 17

needle (with needle count

higher than #22)

❻

: Marker line for DP x 17

needle (with needle count

lower than #22)

❸

:

When DP x 17 needle

(of which needle count is

lower than #22) is used.

❸

:

When DP x 17 needle

(of which needle count is

higher than #22) is used.

* Turn ON the power once, and turn OFF the

power again after making the intermediate

presser in the lowered state.

1) Turn hook driving shaft pulley

❶

by hand and

adjust lower engraved marker line

❸

to the

bottom end of needle bar lower metal

❹

when

needle bar

❷

goes up.

III. MAINTENANCE OF SAWING MACHINE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❶

❷

❶

❹

❸

❺

❻

❹

❻

❸

❹

❺

❷

❶

❸

❹