VA7820-HGx-2 / VA7830-HGx-2

2

Custom input signal

DIP SWITCH 3 = ON - Max range 0-10 V DC or 0-20 mA

(See Table 1 “DIP Switch setting”).

• The custom input signal limits must be applied during the self

-

calibration cycle.

• FIRST, set the

minimum

input signal (start-point), within the range

0…6 V DC

(0…12 mA) and confirm it by pressing the calibration button.

• LED illuminates a steady green for 2 sec. indicating correct entry.

If the LED illuminates a steady yellow for 2 sec., an incorrect setting is indicated and

must be re-entered.

• Set the

maximum

input signal, within the range

3…10 V DC

(6…20 mA) and confirm it by pressing the calibration button.

• LED illuminates a steady green for 2 sec. indicating correct entry.

• When the procedure is finished the actuator returns to its operating mode, reaching

the position corresponding to the input signal value, the LED will illuminate a steady

green.

• If the control signal changes, the actuator stem will move to the new position.

During the stem movement the LED flashes green.

Normal operating mode

• The actuator position is indicated by the end stroke cursors on the yoke.

• When the actuator moves, the green LED blinks.

• When the actuator stops, the green LED switches ON steady.

Actuator status indication

The actuator microprocessor carries out a diagnostics when a failure has been

detected. The actuator status is indicated by the LED. When the microprocessor detects

that the stem has come to an unexpected stop it initiates a retry cycle, this is repeated

three times and if unsuccessful the actuator status is switched to fault mode, the yellow

LED blinks.

If the problem is cleared during the retry cycles, the actuator continues its normal

function.

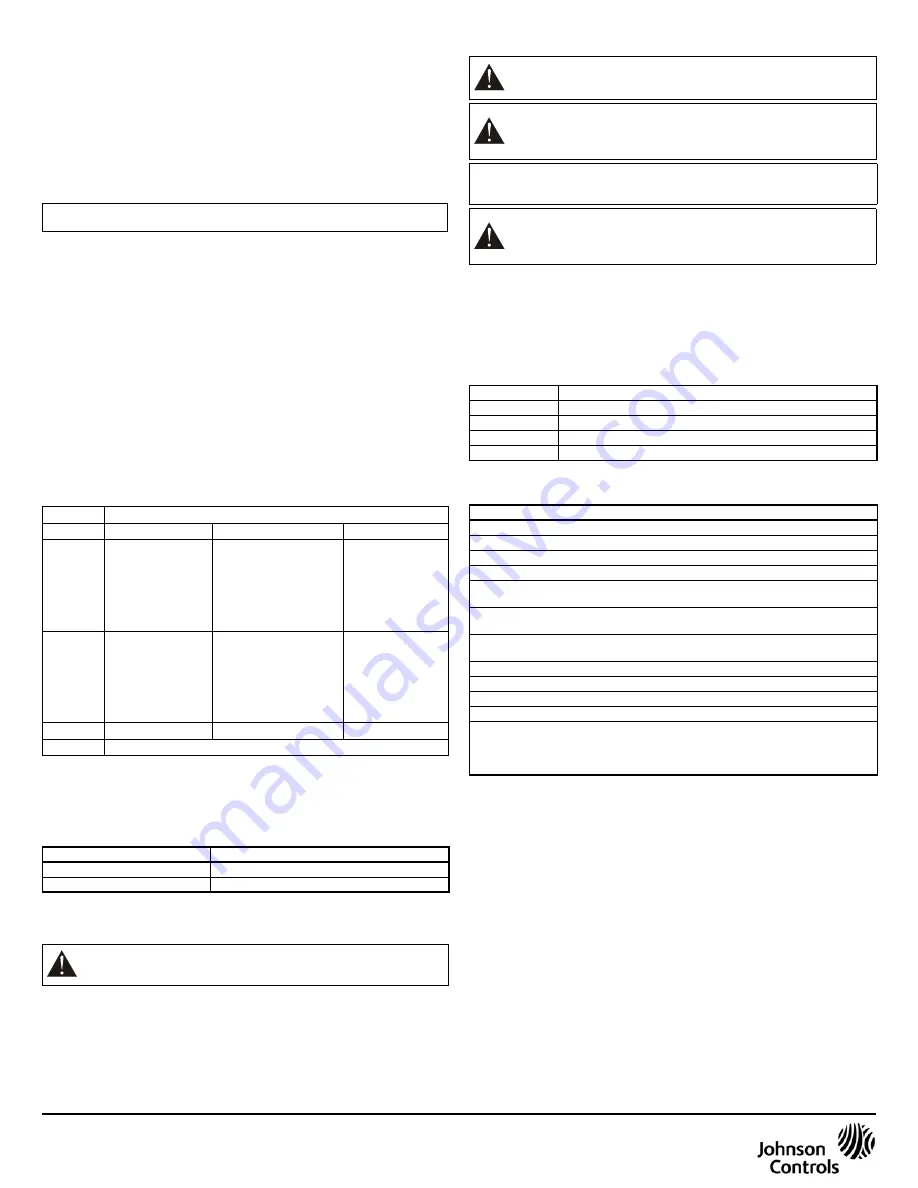

Table 2: LED indications

* If the sticking cause is removed, the actuator leaves the temporary fault mode pushing

the calibration button for at least 5 s.

**The LED switches back to green when the temperature is back to the an allowed

temperature value.

Table 3: Feedback output

Figure 7:

Auxiliary Switches setting

(a).

CAM for auxiliary switches.

The auxiliary switches can be adjusted by means of the two cams.

Safety Warnings

• Do not repair or replace a damaged cable, contact the nearest Johnson Controls

®

commercial system wholesaler.

• Do not open the actuator other then aux switches or feedback setting.

Check out procedure

Before leaving the installation observe at least three complete operating cycles to be

sure that all components are functioning correctly. If not, please contact your supplier.

Ordering Code

Technical Specifications

IMPORTANT:

If the LED illuminates a steady yellow for 2 sec., an incorrect setting is

indicated and the whole procedure must be restarted.

LED color

Status

Green

Yellow

Red

On

Power on - motor still

• Custom calibration

value out of range

• Self

-

calibration rejected.

Valve stroke out of limit

(<0.315 >0.98 in.)

(<8, >25 mm).

Motor still.

Generic fault

Blink

Motor running

• Temporary fault,

possible valve sticking

*

• Self

-

calibration rejected.

Valve stroke out of limits

(<0.315 >0.98 in.)

(<8, >25 mm).

Motor running.

High temperature

**

Fast blink

Calibrating

Input signal failure

Off

Power off

Input signal

Feedback output

0...10 V or 0...20 mA

0...10 V

2...10 V or 4...20 mA

2...10 V

WARNING: Take care that auxiliary switches S1 and S2 are NOT

connected to different voltages.

(E.g. S1 120V and S2 24V NO!, S1 120V and S2 120V OK!).

CAUTION: Risk of Electric Shock.

Disconnect the power supply before making electrical connections to avoid

electric shock.

CAUTION: Risk of Electric Shock.

Disconnect supply power to the VA7820 / VA7830 Series Electric Spring

Return Valve Actuator before attempting to adjust the cover. Failure to

disconnect the supply power may result in electric shock.

IMPORTANT:

Make all wiring connections in accordance with local, national, and

regional regulations. Do not exceed the electrical ratings of the VA7820 / VA7830

Series Electric Spring Return Valve Actuator.

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking all wiring connections.

Short circuited or improperly connected wires may result in permanent

damage to the equipment.

Code

Description

VA7820-HGA-2

Spring Return Extend, Proportional 24 V~

VA7820-HGC-2

Spring Return Extend, Proportional 24 V~, 2 auxiliary switches

VA7830-HGA-2

Spring Return Retract, Proportional 24 V~

VA7830-HGC-2

Spring Return Retract, Proportional 24 V~, 2 auxiliary switches

Product VA7820-HGx

/

VA7830-HGx-2

Thrust Force

225 lb

(1000 N)

Power Supply

24 V~ (19…30 V~) 50/60 Hz, Class 2 Supply

Power Consumption

11 VA

Auxiliary Switch rating

230 V~ 1 A G.P. 3 A RES. 1/4 HP 6k cycles

Ambient Operating

Conditions

23 at 131°F

(-5 at 55°C)

10 at 90% RH (non

-

condensing)

Ambient Storage

Conditions

-40 at 176°F

(-40 at 80°C)

5 at 95% RH (non

-

condensing)

Feedback signal

0...10 V, with input signal 0...10 V or 0...20 mA

2...10 V, with input signal 2...10 V or 4...20 mA

Dimensions (H x W x D)

9.09 x 4.53 x 8.35 in.

(231 x 115 x 212 mm)

Housing Material

Self-extinguishing to UL94-V0

Protection Class

IP54 (IEC 60529)

Shipping Weight

116

.

4 oz.

(3

.

3 Kg)

Compliance

UL 60730 Listed Type 1 Enclosure,

File E194024 XAPX, XAPX7, CAN/CSA E60730-1

CE Mark, EMC Directive 89/336/EEC,

Low Voltage Directive 73/23/EEC