TFP620

Page 7 of 8

Care and

Maintenance

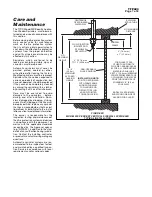

The TYCO Model WS Specific Applica-

tion Window Sprinklers must be main-

tained and serviced in accordance with

this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

systems from the proper authorities

and notify all personnel who may be

affected by this action.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers - before,

during, and after installation. Sprin-

klers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprinkler

that has a cracked bulb or that has lost

liquid from its bulb. Refer to the Instal-

lation section for additional information.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

recognized by the Approval agency

(e.g., NFPA 25), in addition to the stan-

dards of any authorities having jurisdic-

tion. Contact the installing contractor

or product manufacturer regarding any

questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

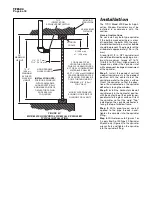

INSTALLATION NOTE:

NO MAXIMUM

ARROW POINTED

MODEL WS SPRINKLER

GLAZING FOR CLARITY

SHOWN ON ONE SIDE OF

TOWARD GLAZING

3" (76,2 mm)

± 1" (25,4 mm)

4" (101,6 mm)

HEIGHT

TO 12" (304,8 mm)

POSITION SPRINKLER

EXPOSED

HEIGHT

GLAZING

13'-0"

MAXIMUM

(3,96 m)

TO GLAZING AND

DEFLECTOR FLOW

ALIGNED PARALLEL

WITH FRAME ARMS

NON-OPERABLE

GLASS WINDOW

FLOW DIRECTION

DEFLECTOR

INDICATED ON

SPRINKLER

MAXIMUM

NO

FRAME

WINDOW

DISTANCE

STRUCTURE

CENTERLINE

OF SPRINKLER

WATERWAY

BUILDING

FOR GLASS TYPES

OTHER THAN FIRELITE

PLUS WS CERAMIC GLASS

BY TGP, ALL COMBUSTIBLE

MATERIALS SHALL BE

KEPT 2" (50,8 mm) MINIMUM

FROM SPRINKLERED FACE

OF GLAZING. THIS MAY BE

DONE THROUGH USE OF

MINIMUM 3'-0" (0,9 m)

PONY WALL

FIGURE 3D

MODEL WS PENDENT VERTICAL SIDEWALL SPRINKLER

TYPICAL INSTALLATION