FRICK

®

POWERPAC

™

INSTALLATION - OPERATION - MAINTENANCE

170.600-IOM (JUN 11)

Page 5

OIL SEPARATOR/RESERVOIR

The oil separator is a horizontal, three-stage design with

integral sump. The separator is designed and constructed

in accordance with ASME Section VIII, Div. 1. Replaceable

coalescent separator elements are provided for final gas/oil

separation of particles down to less than 1 micron.

OIL COOLING

The compressor oil is cooled using a semiwelded plate heat

exchanger that is integral with the refrigerant condenser. The

heat exchanger plates are AISI 316 stainless steel construc-

tion. Maximum design working pressure is 300 or 400 psig.

MOTOR

A factory-mounted flanged motor is close-coupled to the

compressor. The compressor/motor assembly requires no

field coupling alignment. Standard motors are open drip

proof (ODP), have class B insulation, and 1.15 service factor.

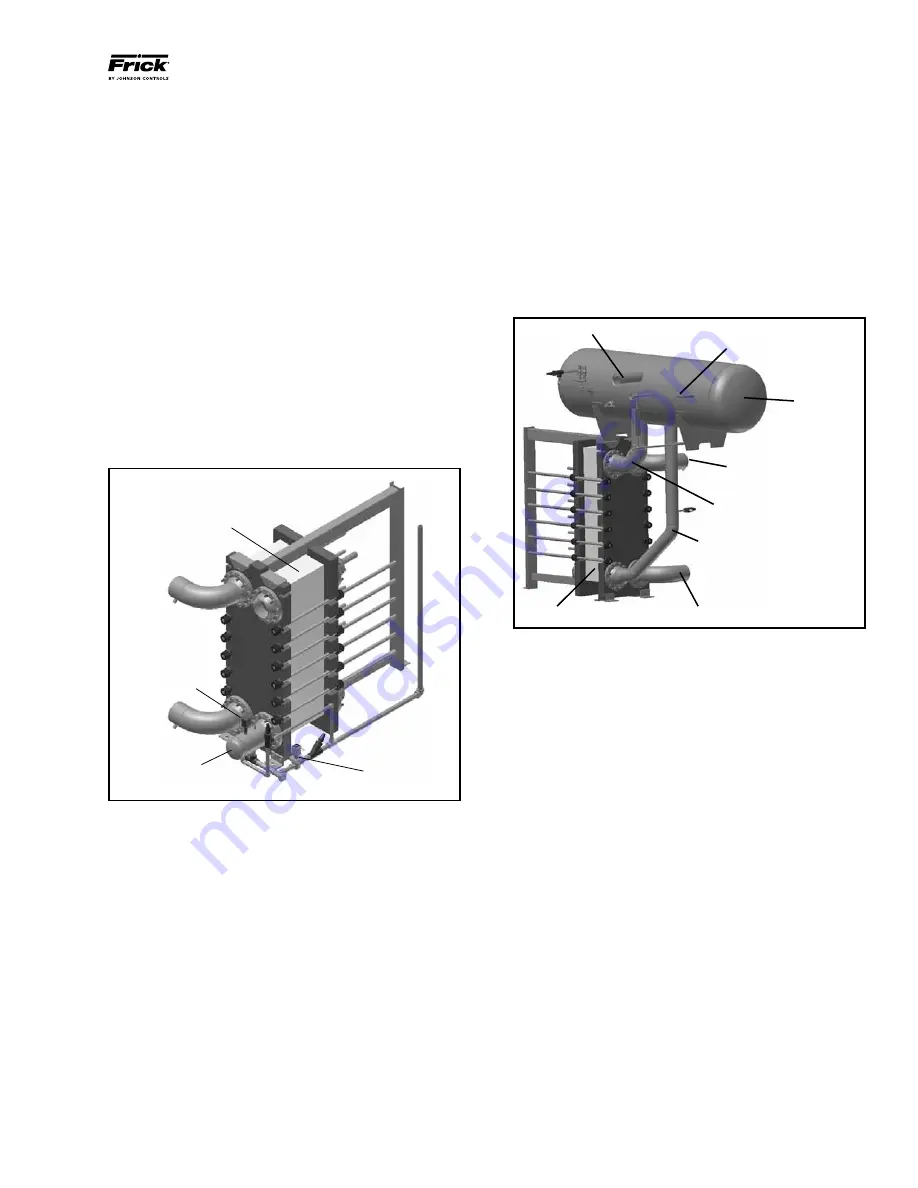

SEMIWELDED PLATE CONDENSER

Condenser

Level Sensor

Level Pipe

Motorized

Expansion

Valve

Figure 1 - Semiwelded Plate Condenser

Semiwelded plate heat exchangers have plates constructed

of AISI 316 Stainless Steel. Gaskets are a two-piece construc-

tion for excellent compatibility with refrigerant and cooling

media. The plate heat exchangers can be disassembled for

easy cleaning and capacity modification.

Like the evaporator, the CPHE condenser is a plate heat

exchanger, and the number of cassettes is exactly adapted

to the current operating conditions. Refrigerant condenses

between the welded plates which make up the cassettes,

and the cooling water circulates in the channels between the

cassettes. The plate condenser may have a built-in oil cooler.

The unit can also be equipped with other types of condensers.

SEMIWELDED PLATE EVAPORATOR

The evaporator is a plate heat exchanger consisting of a

number of cassettes carefully adapted to the actual operating

conditions. The cassettes are assembled/bolted together in

a frame made for the actual design pressure. The refriger-

ant evaporates inside the cassettes and brine is cooled on

the outside.

The evaporator in Figure 2 is of the flooded type, which

means that it is filled with boiling refrigerant. This liquid

leaves the liquid separator and is led to the evaporator

through the drop leg.

Evaporator

Drop Leg

Brine/Water Outlet

Wet Return

Brine/Water Inlet

Liquid Makeup

Liquid

Separator

Dry Suction

Figure 2 - Semiwelded Plate Evaporator

When the water or brine is cooled in the evaporator on its

way through the brine/water connections, the refrigerant

boils and a mixture of liquid and vapor flows through the

wet return and into the liquid separator. From here the su-

perheated vapor is led to the compressor through the dry

suction while the separated liquid is collected at the bottom

of the liquid separator. The system is self-circulating and

needs no pump on the refrigerant side. Liquid runs from the

high pressure side and is supplied to the liquid separator

through the liquid makeup line.

QUANTUM

™

LX CONTROL CENTER

The Quantum

™

LX is a control and monitoring system for

supervision and regulation of the chiller unit. It is factory

mounted and completely wired with all required safety and

operating devices. The control system includes as standard

a single NEMA 4 control panel housing, microprocessor

control, and electrical termination points. Included in the

microprocessor is time-proportioning capacity control, first-

out annunciation, prealarms, volume ratio controls, real-time

clock control, access code protection, lead-lag sequencing,

alternate suction pressure operation, trending, and more.

The operating conditions at the time of the compressor’s

last ten alarms or shutdowns are stored in memory, providing

the ultimate in service and troubleshooting convenience. A

built-in telecommunications interface is standard, enabling

connection to a remote computer or control device.