RXF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.410-IOM (JAN 12)

Page 31

Figure 33

The first step in effective problem solving is to define the

limits of the problem. If, for example, the compres sor pe-

riodically experienc es high oil tempera tures, do not rely on

this observation alone to help identify the problem. On the

basis of this information, the apparent corrective measure

would appear to be a re adjustment of the liquid injection

system. Lowering the equalizing pressure on the thermal

expansion valve would in crease the refriger ant feed and the

oil temperature should drop.

If the high oil temperature was the result of high suction

superheat, however, and not just a matter of improper liquid

injection adjust ment, increasing the liquid feed could lead to

other problems. Under low load conditions the liquid injection

system may have a tendency to overfeed. The high suction

superheat condition, moreov er, may only be tempor ary.

When system conditions return to normal, the unit's liquid

injection will overfeed and oil temperature will drop. In solv-

ing the wrong problem a new problem was creat ed.

The following list of abnormal system condi tions can cause

abnormal operation of the RXF compressor unit:

1. Insufficient or excessive refrigeration load.

2. Excessively high suction pressure.

3. Excessively high suction superheat.

4. Excessively high discharge pressure.

5. Inadequate refrigerant charge or low receiv er level.

6. Excessively high or low temperature coolant to the oil

cooler.

7. Liquid return from system (carryover).

8. Refrigerant underfeed or overfeed to evapor ators.

9. Blocked tubes or plates in water-cooled oil cooler from

high mineral content of water.

10. Insufficient evaporator or condenser siz ing.

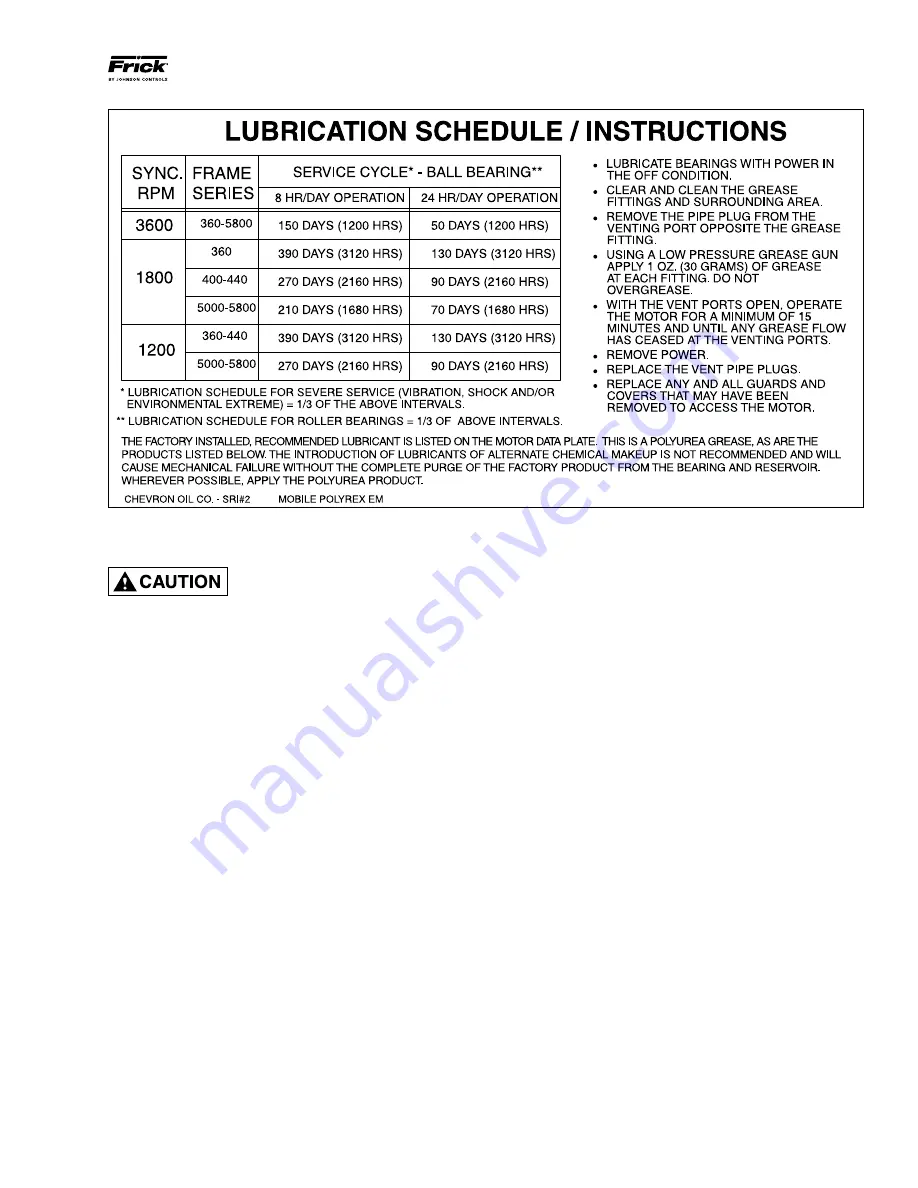

MOTOR BEARINGS

Lubricate motor bearings properly

before start-up. Maintain subse-

quent lubrication as recommended

by the motor manufacturer. See Figure 33.

OPERATING LOG

The use of an operating log, as shown in this manual (see

Table of Contents...FORMS), permits thorough analysis of

the operation of a refrigeration system by those responsible

for its maintenance and servicing. Continual recording of

gauge pressures, temperatures, and other pertinent informa-

tion enables the observer and serviceman to be constantly

familiar with the operation of the system and to recognize

immediately any deviations from normal operating condi-

tions. It is recommended that readings be taken at least

every four hours.

TROUBLESHOOTING GUIDE

Successful problem solving requires an organ ized ap proach to

define the problem, identify the cause, and make the proper

correction. Sometimes it is possible that two relatively obvi-

ous problems combine to provide a set of symptoms that

can mislead the troubleshooter. Be aware of this possibility

and avoid solving the “wrong problem”.

ABNORMAL OPERATION

ANALYSIS and CORRECTION

Four logical steps are required to analyze an opera tional

problem effectively and make the necessary correc tions:

1. Define the problem and its limits.

2. Identify all possible causes.

3. Test each cause until the source of the problem is found.

4. Make the necessary corrections.