INSPECTION

Upon receipt of equipment, carefully check all items

against the bill of lading to ensure that all equipment

has been received. Note any discrepancy on the bill of

lading before signing.

Inspect all equipment for any signs of damage caused

during transit. Note any visual damage on the bill of

lading before signing. Immediately report all visual

and concealed damage to the carrier and file a claim.

INTRODUCTION

General

In order to ensure long and trouble free life, the

equipment should have proper care and maintenance.

Enough space should be left around the unit for service

and repair, see .

Equipment, as shipped, is factory assembled as far

as job specifications and shipping limitations allow.

Where field assembly is required, bolts, nuts, screws

and gasketing material are provided with each module.

Modules bolt together from the inside of the upstream

module.

UNIT IDENTIFICATION

To ensure the assembled MQL modules are in the

proper sequence, each module has an identifying code

and an airflow direction label. The proper assembly

sequence is listed on the supply fan nametag. The first

listed module is the first section in the direction of air-

flow.

HAND IDENTIFICATION

Coil connections and other components are located

and described as left or right hand. The proper orienta-

tion to describe the proper hand is when airflow is at

your back. Vertical stacked top sections maintain the

same handling as lower section. See

RIGGING AND HANDLING

The MQL air handler can ship as separate modules,

fully assembled, or in separately assembled sections

depending on the unit size and application. The equip-

ment must be rigged as it was shipped from the factory.

Do not remove shipping skid or protective cover until

equipment is ready for final placement, as damage to

equipment can result. Do not remove protective caps

from piping connections until ready to connect piping.

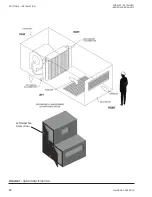

FIGURE 1 -

LIFT POINTS FOR UNITS WITH BASE RAILS

JOHNSON CONTROLS

9

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013

1

SECTION 1 - INTRODUCTION