501562-UIM-A-0909

Johnson Controls Unitary Products

3

GROUND INSTALLATION

The unit may be installed at ground level on a solid base that will not

shift or settle, causing strain on the refrigerant lines and possible leaks.

Maintain the clearances shown in Figure 1 and install the unit in a level

position.

Normal operating sound levels may be objectionable if the unit is placed

directly under windows of certain rooms (bedrooms, study, etc.).

Isolate the unit from rain gutters to avoid any possible wash out of the

foundation.

ROOF INSTALLATION

When installing units on a roof, the structure must be capable of sup-

porting the total weight of the unit, including a pad, lintels, rails, etc.,

which should be used to minimize the transmission of sound or vibra-

tion into the conditioned space.

UNIT PLACEMENT

1.

Provide a base in the pre-determined location.

2.

Remove the shipping carton and inspect for possible damage.

3.

Compressor tie-down bolts should remain tightened.

4.

Position the unit on the base provided.

LIQUID LINE FILTER-DRIER

The air conditioning unit’s copper spun filter/dryer is located on the liq-

uid line.

NOTE:

Replacements for the liquid line drier must be exactly the same

as marked on the original factory drier. See Source 1 for O.E.M.

replacement driers.

PIPING CONNECTIONS

The outdoor condensing unit must be connected to the indoor evapora-

tor coil using field supplied refrigerant grade copper tubing that is inter-

nally clean and dry. Units should be installed only with the tubing sizes

for approved system combinations as specified in tabular data sheet.

The charge given is applicable for total tubing lengths up to 15 feet. See

Application Data Part Number 036-61920-000 for installing tubing of

longer lengths and elevation differences.

NOTE:

Using a larger than specified line size could result in oil return

problems. Using too small a line will result in loss of capacity and other

problems caused by insufficient refrigerant flow. Slope horizontal vapor

lines at least 1" every 20 feet toward the outdoor unit to facilitate proper

oil return.

PRECAUTIONS DURING LINE INSTALLATION

1.

Install the lines with as few bends as possible. Care must be taken

not to damage the couplings or kink the tubing. Use clean hard

drawn copper tubing where no appreciable amount of bending

around obstruction is necessary. If soft copper must be used, care

must be taken to avoid sharp bends which may cause a restriction.

2.

The lines should be installed so that they will not obstruct service

access to the coil, air handling system, or filter.

3.

Care must also be taken to isolate the refrigerant lines to minimize

noise transmission from the equipment to the structure.

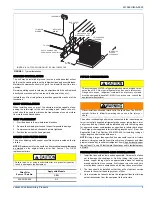

FIGURE 1:

Typical Installation

THERMOSTAT

NEC CLASS 1

WIRING

TO INDOOR

BLOWER

NEC CLASS 2

WIRING

TO COIL

WEATHERPROOF

DISCONNECT SWITCH

48” OVERHEAD

CLEARANCE

24” SERVICE

ACCESS

CLEARANCE

18” FRONT

& SIDES

NOTE:

ALL OUTDOOR WIRING MUST BE WEATHERPROOF

SEAL OPENINGS WITH

PERMAGUM OR EQUIVALENT

Failure to do so or using a substitute drier or a granular type may

result in damage to the equipment.

Filter-Drier

Source 1 Part No.

Apply with Models

CZH

029-22195-000

All

This system uses R-410A refrigerant which operates at higher pres-

sures than R-22. No other refrigerant may be used in this system.

Gauge sets, hoses, refrigerant containers, and recovery systems

must be designed to handle R-410A. If you are unsure, consult the

equipment manufacturer.

Never install a suction-line filter drier in the liquid line of an R-410A

system. Failure to follow this warning can cause a fire, injury or

death.