5165697-BUM-C-0818

Johnson Controls Unitary Products

7

SEQUENCE OF OPERATION

Continuous Blower

On cooling/heating thermostats with fan switch, when the fan switch is

set in the ON position, a circuit is completed between terminals R and G

of the thermostat. The blower motor is energized through the cool fan

terminal on the ignition control module.

Intermittent Blower - Cooling

On cooling/heating thermostats with fan switch, when the fan switch is

set in the auto position and the thermostat calls for cooling, a circuit is

completed between the R, Y and G terminals. The motor is energized

through the cool fan terminal and runs on the selected speed. The fan

off setting is fixed at 60 seconds for SEER enhancement.

Heating Cycle

When the system switch is set on HEAT and the fan is set on AUTO,

and the room thermostat calls for heat, a circuit is completed between

terminals R and W of the thermostat. When the proper amount of com-

bustion air is being provided, a pressure switch activates the ignition

control.

The ignition control provides a 30-second warm-up period. The gas

valve then opens for 10 seconds. If the flame is not detected within 2

seconds of the gas valve opening, the gas valve is shut off and a retry

operation begins. If the flame is lost for 2 seconds during the 10 second

stabilization period, the gas valve is shut off and a retry operation

begins. During a retry operation the ventor starts a 15 second inter-

purge and the ignitor warm-up time is extended to 27 seconds. If the

flame is established for more than 10 seconds after ignition, during a

retry, the control will clear the ignition attempt (retry) counter. If three

retries occur during a call for heat, the furnace will shut down for one

hour. If at the end of the one hour shut down there is a call for heat, the

furnace will initiate a normal start cycle. If the problem has not been cor-

rected the furnace will again lockout after three retries.

A momentary loss of gas supply, flame blowout, or a faulty flame probe

circuit will result in a disruption in the flame and be sensed within 0.8

seconds. The gas valve will de-energize and the control will begin a

recycle operation. A normal ignition sequence will begin after a 15 sec-

ond inter-purge. If during the three recycles the gas supply does not

return, or the fault condition is not corrected the ignition control will lock-

out for 60 minutes.

During burner operation, a momentary loss of power for 50 milliseconds

or longer will de-energize the gas valve. When the power is restored,

the gas valve will remain de-energized and the ignition sequence will

immediately restart.

As the gas starts to flow and ignition occurs, the flame sensor begins its

sensing function. If a flame is detected during the 10 second flame sta-

bilization period the circulating blower will energize 30 seconds after the

gas valve opens (20 seconds after the flame stabilization period ends).

Normal furnace operation will continue until the thermostat circuit

between R and W is opened. When the thermostat circuit opens, the

ignition control is de-energized. When the ignition control is de-ener-

gized, the gas flow stops, and the burner flames are extinguished. The

ventor continues to operate for 15 seconds after the gas flow stops.

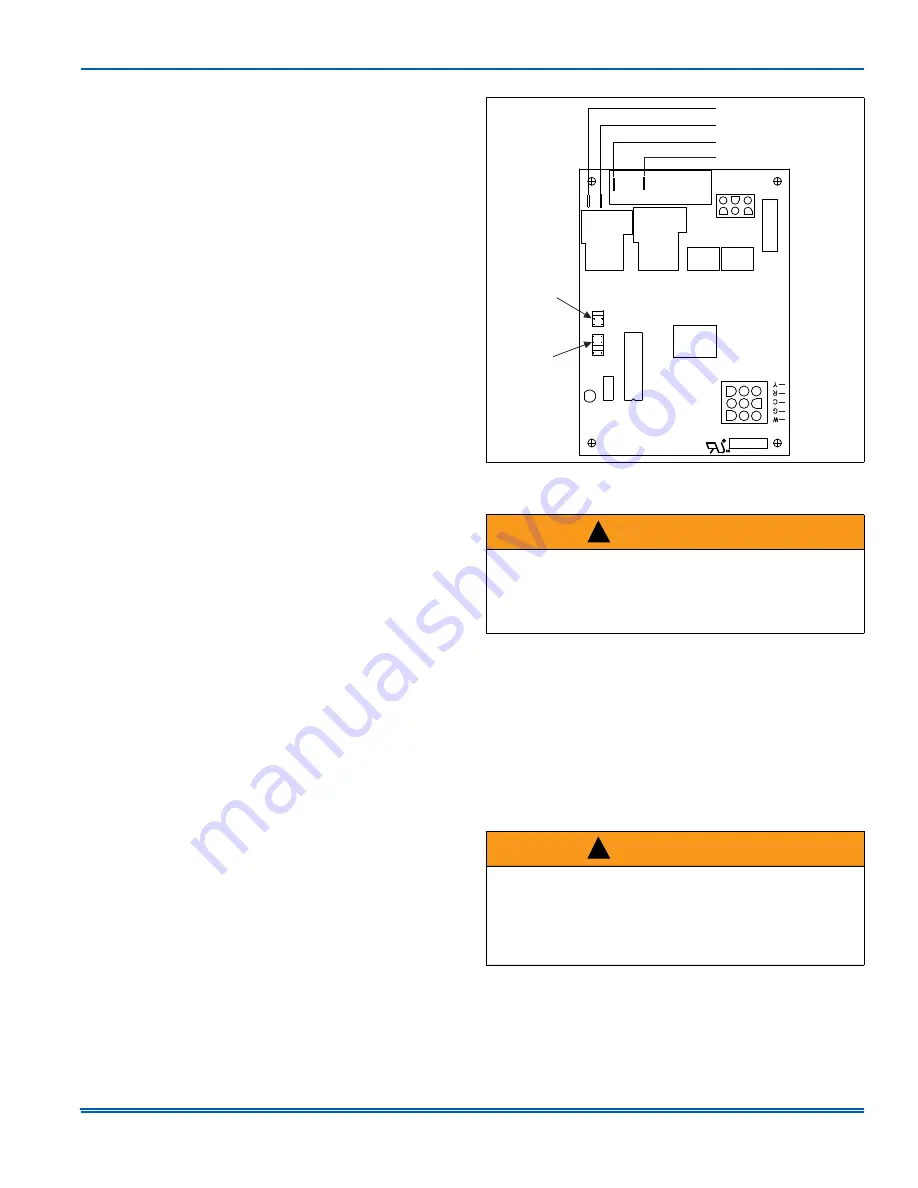

The blower motor continues to operate for the amount of time set by the

fan-off delay “Jumper” located on the ignition control board. Refer to

Figure 6. The heating cycle is complete, and the furnace is ready for the

start of the next heating cycle.

Hot Surface Ignition System

TROUBLESHOOTING

The following visual checks should be made before troubleshooting:

1. Check to see that the power to the furnace and the ignition control

module is ON.

2. The manual shut-off valves in the gas line to the furnace must be

open.

3. Make sure all wiring connections are secure.

4. Review the sequence of operation. Start the system by setting the

thermostat above the room temperature. Observe the system’s

response. Then use the troubleshooting section in this manual to

check the system’s operation.

FIGURE 6:

Furnace Control Board

WARNING

HOT SURFACE IGNITION SYSTEM

Do not attempt to light this furnace by hand (with a match or any other

means). There may be a potential shock hazard from the components

of the hot surface ignition system. The furnace can only be lit auto-

matically by its hot surface ignition system.

WARNING

Never bypass pressure switch to allow furnace operation. To do

so will allow furnace to operate under potentially hazardous con-

ditions.

Do not try to repair controls. Replace defective controls with

UPG Source 1 Parts.

Never adjust pressure switch to allow furnace operation.

)$121

)$&725<

35(6(7

-803(5

+($

7

;)05

/

&22/

75$16)250(5

/,1(92/7$*(

%/$&.+,*+63(('

5('/2:63(('

)$12))

-803(5

1(875$/6

)86($

$

!

!