5. MAINTENANCE

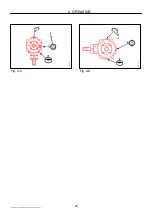

Fig. 5-16 The PTO drive shaft for the cutter bar has been greased for life. The PTO should run

with minimum angle deviation, i.e. the measure difference at A and B should

maximum be 6 mm (+/- 3).

The alignment is made at the gearbox above the shaft by moving the gearbox in the

oblong holes or mount fillers between the gearbox and the frame at C.

The bolts D are tightened with 60 Nm (6 Kpm) and must be locked with LocTite.

Fig. 5-17 The spring washer (1) above the input disc is placed as shown with the curved side

upwards.

The nut (2) is tightened to 190 Nm (19 Kpm).

The bolts (3) which hold the disc bearing housing to the bar are tightened to 85 Nm

(8.5 Kpm).

WARNING:

After replacement of blades, blade bolts, nuts or discs check

that no tools have been left on the machine.

CONDITIONER

Defective fingers on the conditioner rotor must be replaced by new ones to ensure

optimal conditioning and transport of the crop. Furthermore, missing fingers or parts

of fingers will cause the rotor to get out of balance which for instance will result in

reduced life of the bearings.

TIGHTENING OF ROLLER CHAIN

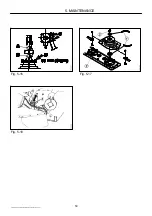

Fig. 5-18 Press the sprocket wheel Z down towards the chain and tighten it.

WINTER STORAGE

When the season is over, the preparation for winter storage should be made

immediately after. First, clean the machine thoroughly. Dust and dirt absorb moisture

and moisture increases the formation of rust. Be careful when cleaning with a high

pressure cleaner. Never spray directly on the bearings and grease all nipples

carefully before and after cleaning so that possible water is pressed out of the

bearings.

The following points are instructions how to prepare for winter storage.

•

Check the machine for wear and other defects – note down the necessary parts

you will need before the next season and order the spare parts.

•

Dismount the PTO drive shafts, lubricate the profile tubes and keep them in a dry

place.

•

Spray the machine with a coat of rust-preventing oil. This is especially important

on the parts polished with use.

•

Change the oil in the cutter bar and the gearboxes.

•

Store the machine in a ventilated engine house.

PIGB-093X-06 GX 2402/2802/3202 SM-GX 2402/2802 SC 0410

51

Содержание GX 3202 SM

Страница 24: ...3 ADJUSTMENTS AND DRIVING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 24 PR12 0018 Fig 3 10 Fig 3 11...

Страница 26: ...3 ADJUSTMENTS AND DRIVING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 26 Fig 3 12 Fig 3 13 Fig 3 14...

Страница 38: ...4 GREASING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 38 Fig 4 5 Fig 4 6...

Страница 40: ...4 GREASING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 40 PR11 0045 E Fig 4 7 Fig 4 8...

Страница 44: ...5 MAINTENANCE PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 44 Fig 5 2 PR12 0709 A B D C Fig 5 3...

Страница 50: ...5 MAINTENANCE PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 50 Fig 5 16 Fig 5 17 Fig 5 18...

Страница 54: ......