12

Grounding Instructions

This Band Saw must be

grounded while in use to protect the operator

from electric shock.

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug that looks similar to the plug in

Figure 10. The plug must be inserted into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided. If it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-

grounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipment-

grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

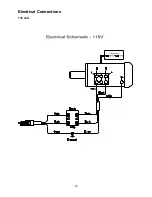

Figure 10

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace a damaged or worn cord

immediately.

115 Volt Operation

As received from the factory, your bandsaw is

ready to run at 115-volt operation. This

bandsaw, when wired for 115 volts, is intended

for use on a circuit that has an outlet and a plug

that looks like the one illustrated in Figure 10. A

temporary adapter, like the adapter in Figure 11,

may be used to connect this plug to a two-pole

receptacle, as shown in Figure 11, if a properly

grounded outlet is not available. The temporary

adapter should only be used until a properly

grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in

Canada. The green colored rigid ear, lug, or

tab, extending from the adapter, must be

connected to a permanent ground such as a

properly grounded outlet box, as shown in

Figure 11.

Figure 11

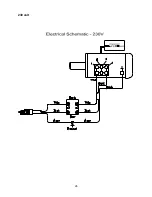

230 Volt Conversion

If 230V, single-phase operation is desired, the

following instructions must be followed:

Disconnect machine from power source.

This band saw is supplied with four motor leads

that are connected for 115V operation, as shown

in Figure 12. Reconnect these four motor leads

for 230V operation, as shown in Figure 12.

Figure 12

The 115V attachment plug supplied with the

band saw must be replaced with a UL/CSA

listed plug suitable for 230V operation, as shown

Содержание JWBS-140S

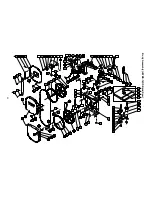

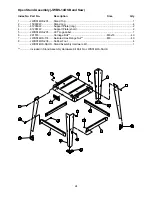

Страница 23: ...23 Body Assembly JWBS 14OS Band Saw...

Страница 25: ...25 Electrical Connections 115 volt...

Страница 26: ...26 230 volt...

Страница 27: ...27 Notes...

Страница 28: ...28 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60123 Phone 800 274 6848 www wmhtoolgroup com...